How We Test Satellites Before Launch

Launch Simulation Testing

MECHANICAL VIBRATION AND ACOUSTIC TESTING

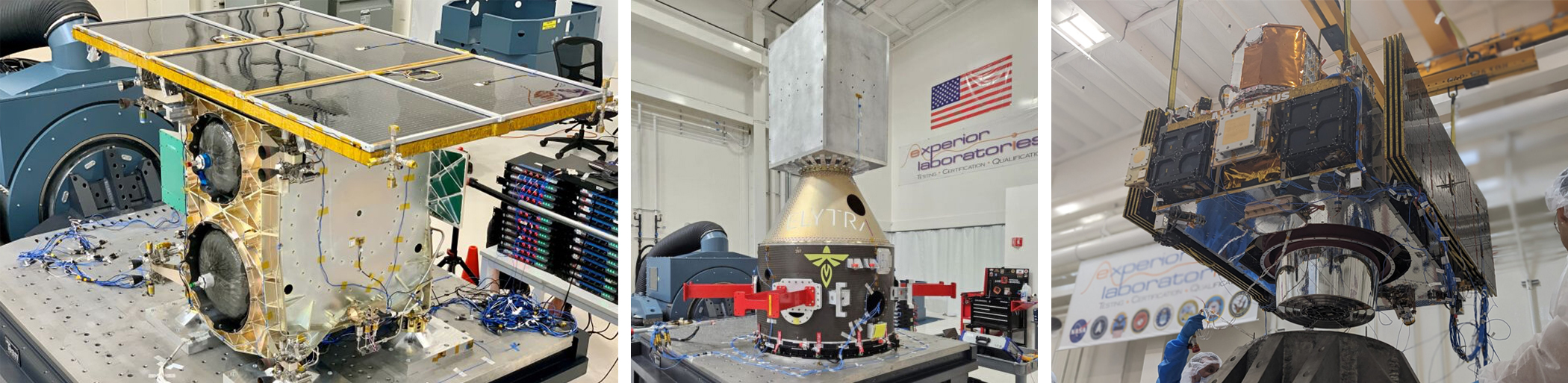

Experior Laboratories specializes in creating high-performing and demanding random and direct-field acoustic vibration that simulates space launch. The vibration testing of spacecraft is a crucial step in the spacecraft development process to ensure that the spacecraft can withstand the mechanical vibrations experienced during launch and other dynamic events. The primary goals of vibration testing are to verify the structural integrity of the spacecraft, assess the functionality of its components, and ensure that it can survive the harsh conditions of a launch.

Space Simulation Testing

THERMAL VACUUM AND FAST-RAMP TEMPERATURE TESTING

Experior Laboratories environmental testing simulate the extreme temperature variations and vacuum conditions encountered in space. Experior labs chambers are capable of handing full-size satellite and subsystems.

Spacecraft Separation Simulation

PYROSHOCK SIMULATION SYSTEM

Experior Laboratories pyroshock simulation systems are used to verify the spacecraft’s ability to withstand shockwaves generated by pyrotechnic devices. These tests Simulate the shocks produced by the activation of separation mechanisms and other explosive devices.

Talk to An Expert

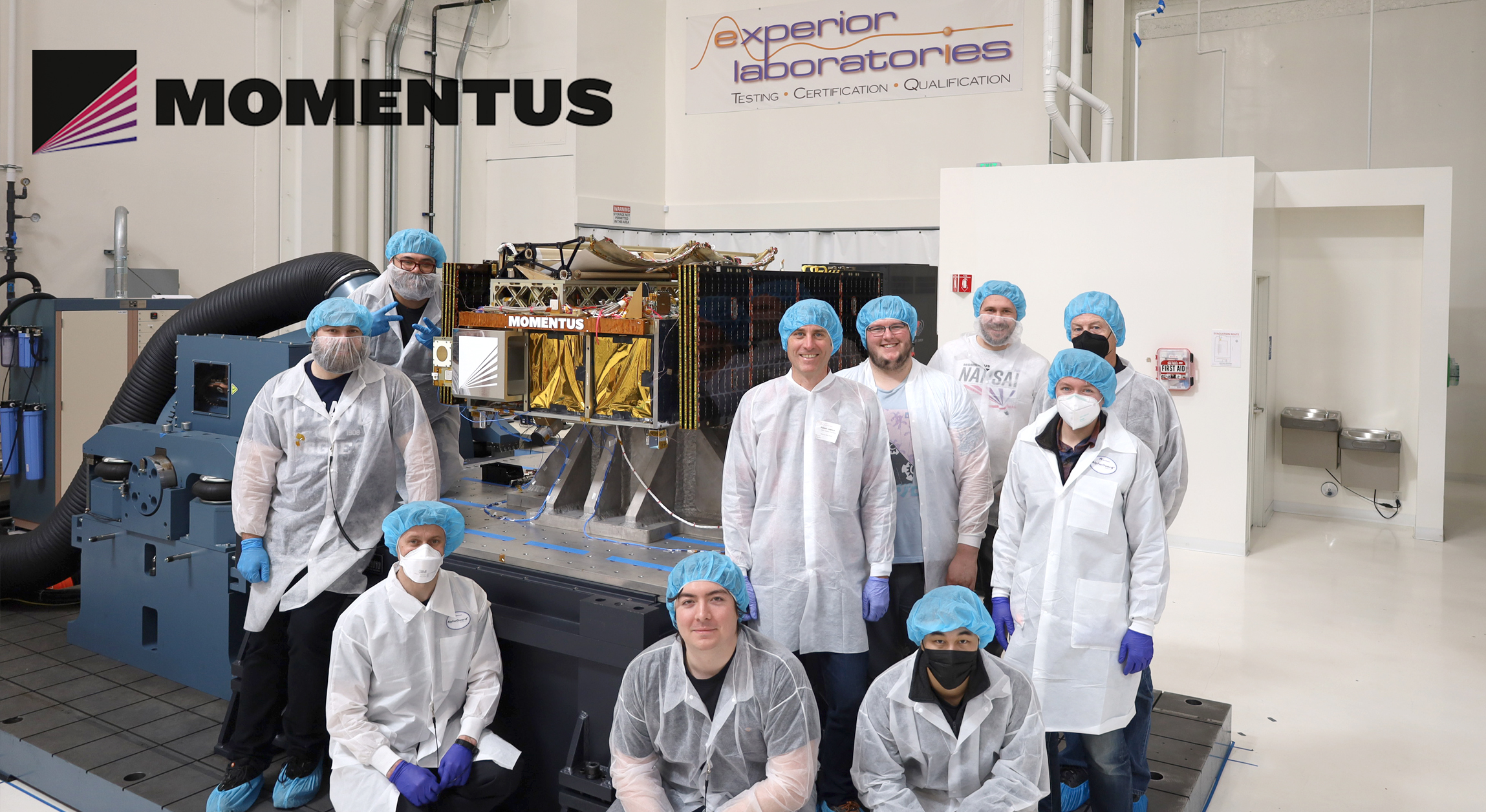

NEWS - Momentus Space

Momentus Completes Vibration Testing of Vigoride 6 Orbital Service Vehicle to launch on SpaceX Transporter 7 mission

NEWS - SpaceX Ride-Share Program

SpaceX Ride-Share Program satellite component and systems qualification and testing

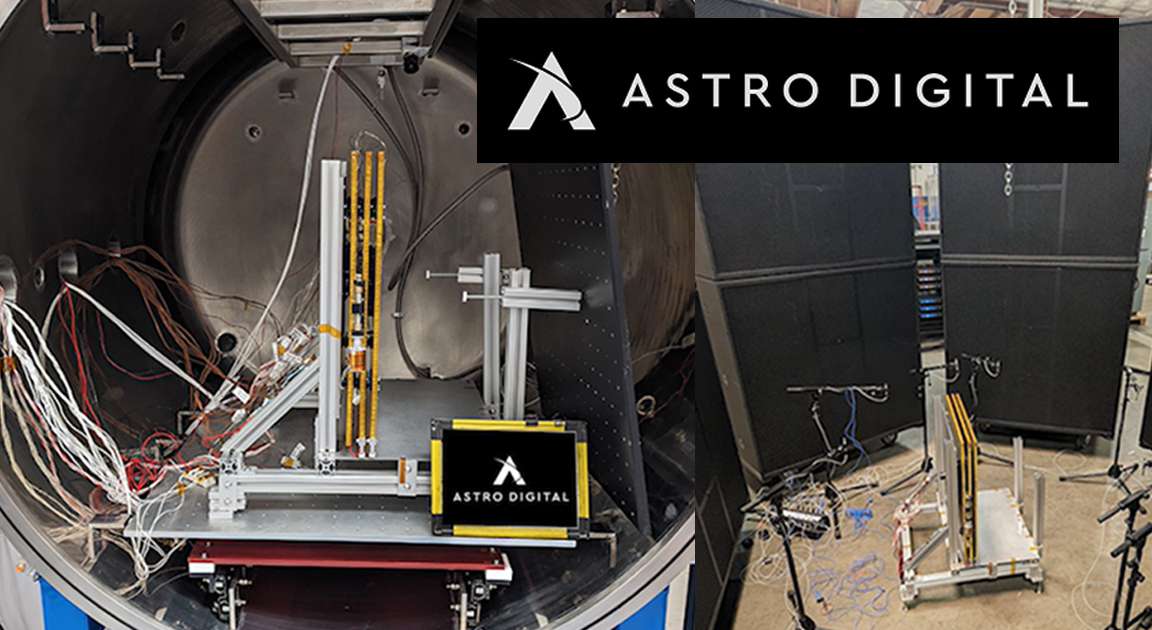

NEWS - Astro Digital

Astro Digital completes Thermal Vacuum and Direct Field Acoustic Noise Test Campaign on Deployable Solar Array.

NEWS - Firefly Aerospace

Firefly Aerospace completed its structural environmental testing on the Elytra qualification model

NEWS - Turion Space

Turion completed vibration qualification testing of their maiden satellite DROID.001

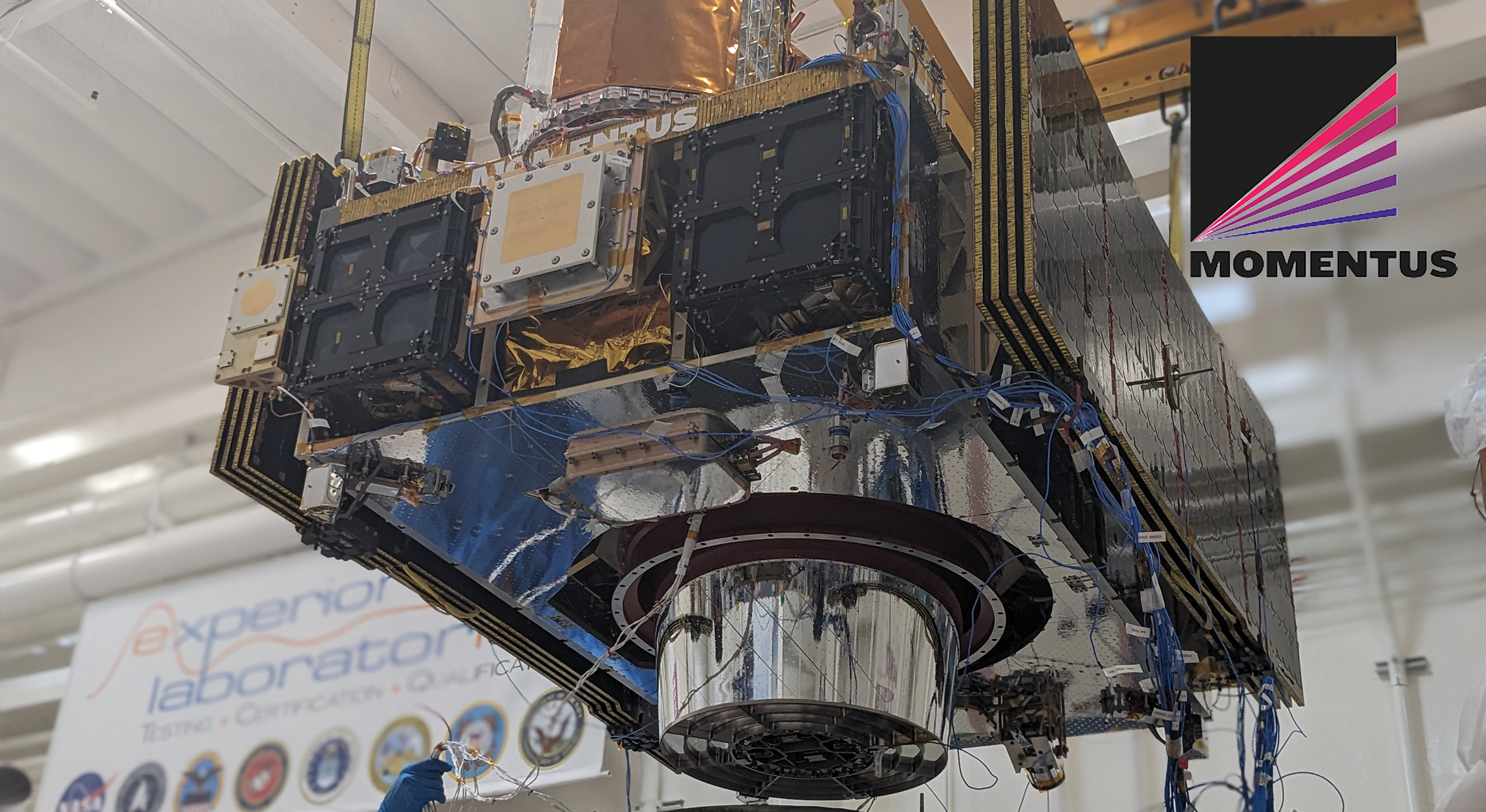

NEWS - Momentus Space

Momentus Completes Vibration Testing of Vigoride-7 Orbital Service Vehicle at Experior Laboratories

NEWS - SpinLaunch

SpinLaunch Satellite completes vibration and thermal vacuum testing of ruggedized components

NEWS - Impulse Space

Impulse Space completed Vibration Testing of their No 1 Mira Spacecraft leading up to their fall launch

NEWS - ARS and Quartus

Successful Direct Field Acoustic Test Demonstration at Experior Laboratories featuring ARS and Quartus Engineering

NEWS - Terran Orbital System

NEWS - XONA Space Systems

NEWS - Momentus Space

NEWS - Sierra Space

NEWS - Aerojet Rocketdyne

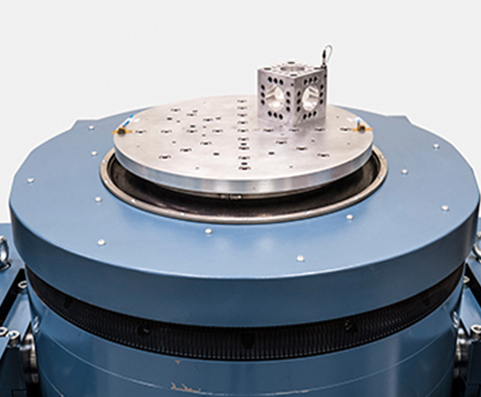

Vibration Testing

Sine Burst Testing Video of a Cal Tech Space Systems

Sine Burst Vibration Testing

The main advantage of the Sine Burst is that it is performed on a vibration system, the same vibration system that performs other tests such as random and/or sine sweep vibration and shock testing. Further, test article sizes can be much larger and heavier than in a Centrifuge. Performing all dynamic tests on the same vibration system reduces test costs and time.

Direct Field Acoustic Testing

Pyroshock

Pyroshock testing simulates the high G, high-frequency shock environment associated with pyrotechnic events, such as rocket stage separations. These are sometimes called “SRS Shock” tests, as they are specified with a Shock Response Spectrum (SRS) profile. This profile is a representation of the maximum predicted acceleration of a system across a range of assumed natural frequencies.

Experior Laboratories’ Kinetic Impact Pyroshock Simulation (KIPS) test systems are able to simulate near and midfield Pyroshock, experienced by components closest to a pyrotechnic event, using a high-speed impact to excite a tunable resonant beam. Adjusting the impact force, location and damping, this platform allows for highly customizable shock generation and the pneumatic systems allow for quick setup and reset.

Adjustable resonance allows boosting acceleration in only the desired frequency range. For shocks with a specified Te (event duration), adjustable muzzle velocity, impact mass, and custom damping materials allow us to customize shock duration while meeting acceleration requirements.

The KIPS test systems offer short transients, narrow differences between positive and negative SRS traces, and a uniform shock input that allows for near-equal measurements at multiple fixture mounting points.

Experior Labs has designed a wide variety of custom shock platforms and fixtures, and we’ve used frequency analysis software to identify mode shapes and resonant frequencies, which lets us prevent cross-axis acceleration and ensure that units are not over-tested.

Shaker Shock

Experior Laboratories performs SRS Shock testing with levels up to 5000 G on the T2000 Shakers, making Experior Labs the industry leader in SRS Shaker Shock. Most test labs cannot offer Shaker Shock testing above 500 – 1,000 G SRS due to risk of shaker armature damage.

Thermal Vacuum

Experior Laboratories’ vacuum test chambers are designed to meet the harsh requirements of space conditions. Experior Labs is capable of simulated space along with repeated cycling between high and low temperature extremes – all while providing test data to better assess likely flight mission performance and function.

Fast Ramp Temperature Testing

Experior Laboratories has several accelerated thermal chambers with high-flow blower motors and liquid nitrogen boost designed to transition temperature as quickly as possible, and are ideal for tests with demanding ramp rates.

Cryogenic

Temperature Testing

Experior Laboratories test facility can simulate extreme low cryogenic temperatures for aerospace, fiberoptic and electrical applications. Our cryogenic chambers have liquid nitrogen and liquid helium tanks piped in for rapid chilling and freezing temperatures.

Many space components require Cryogenics Testing for parts and instruments exposed to the extreme temperatures in rockets and orbit.

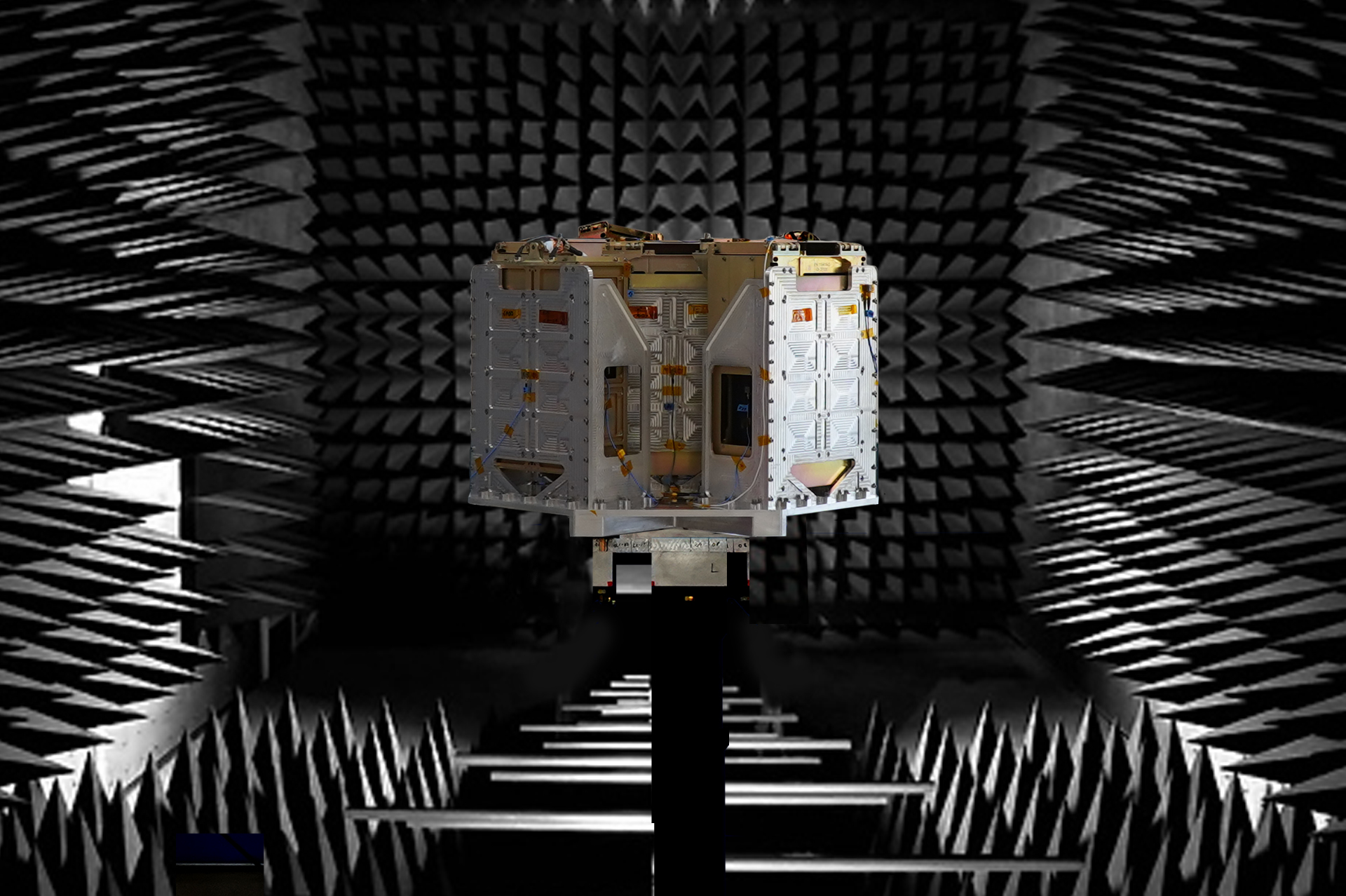

EMI/EMC/HIRF

Experior Laboratories, Inc and DNB Engineering, Inc. are partnering with the mutual goal of offering the most comprehensive overall service portfolio and generating substantial impact for strategic proposals. The partnership promises to provide a superior client experience to our customers within the Aerospace, Military, Automotive, Telecommunication, and Medical industries.

Cleanroom Capacity

Experior Laboratories’ 11,000 square foot dynamics testing facility is an ISO8 / Class 100,000 compliant cleanroom, verified and monitored to operate within a temperature range of 71.6°F ± 5.4°F and humidity range of 45% ± 15%.

Portable Class 100,000 Cleanroom

Experior Labs also offers portable Class 100,000 cleanroom capability to turn any workspace into a cleanroom workspace.