Vibration Testing

Vibration Testing

Experior Laboratories’ MIL-STD-790, NASA and JPL approved and ISO/IEC 17025:2017 accredited laboratory houses multiple state-of-the-art electrodynamic vibration testing systems that can handle the most demanding vibration and shock testing specifications.

For oversized and heavy payload vibration testing applications, Experior Labs’ vibration testing systems can be used in tandem to provide a combined 80,000 lbf for large articles. Such applications have included rocket engines, rocket stage separation actuators, satellites, orbital reflectors, electric vehicle batteries, railroad components and many more. Custom-made vibration testing fixtures and slip plates allow us to test parts of almost any shape and size.

Vibration Testing Capabilities

• Sine sweep Vibration Testing: >220 G pk

• Random Vibration Testing: >175 G rms

• Cleanroom Option Available

• Combined Environments: Vibration at hot and cold Temperatures

• Up to > 300 Channels of Vibration Testing Data Recording

• Time history data recording up to 200kHz

Applications

• Sine Sweep Vibration Testing

• Sine Dwell Vibration Testing

• Sine Burst Vibration Testing

• Random Vibration Testing

• Sine on Random Testing

• Random on Random Testing

• Windmilling•Vibration Testing

• Gunfire Vibration Testing

• Cargo & Transportation Vibration

72” Custom Guided Head Expander Capability

Experior Laboratories’ vertical vibration system features a custom-designed 72” x 72” guided head expander that offers the best dynamic response for vibration testing of large and heavy test articles.

High Performance Vibration Testing for Large and Heavy Test Articles

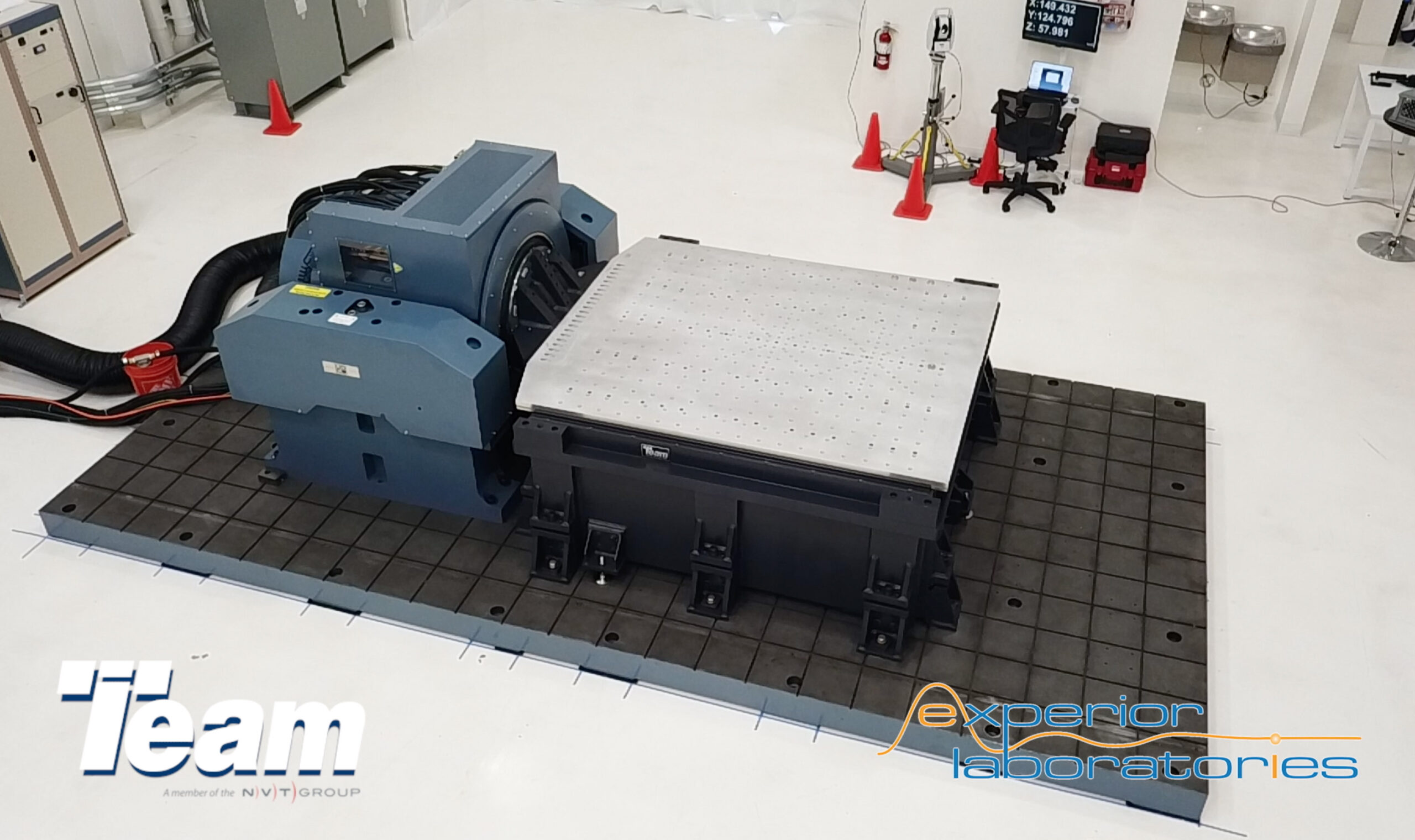

The newly installed system combines two test industry expert components, a new Unholtz Dickie T4000 vibration system and a TEAM T-Film Bearing slip table.

The TEAM T-Film bearings have several benefits overs standard oil film and linear bearings. The unique inverted T shape of TEAM bearings provides improved stiffness, load transfer and improved moment transfer to the reaction base. This minimizes slip plate deflection and cross axis vibration, as well as allows for test articles with a much higher overturning moment. The hydrostatic bearings have significantly increased load capability, meaning the table can accommodate much heavier test articles.

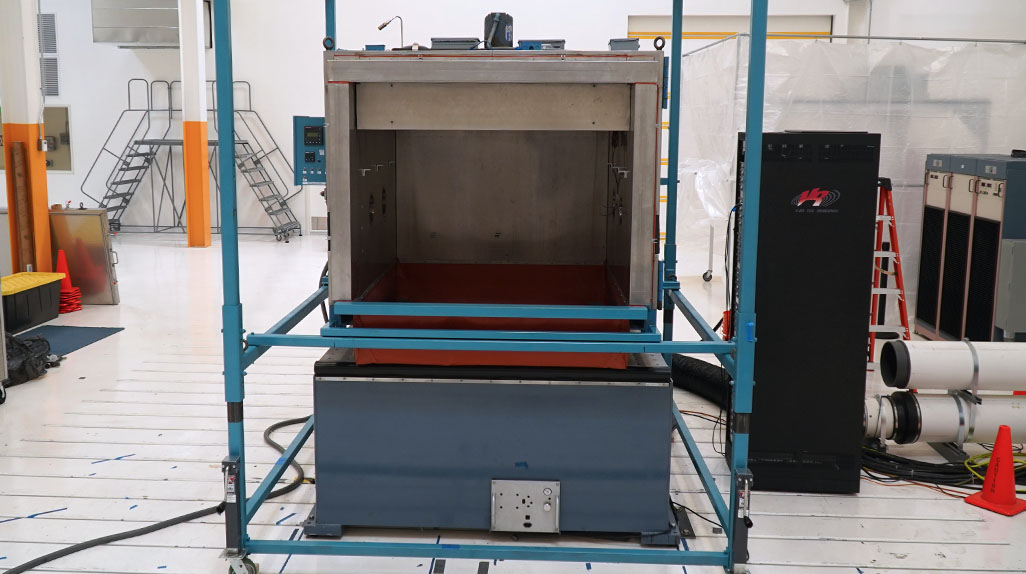

Vibration Testing at Temperature

Standard Temperature chambers range from -75°C to +200°C. All chambers feature portholes for routing supply lines and/or signal cables to and from the equipment under test and all are equipped with electronic data acquisition monitoring to allow real-time charting of climatic conditions through data files and spreadsheets. Custom and non-standard temperatures available. Contact us for more information.

Video of Vibration Testing at Temperature

Vibration testing at temperature of Mil/Aero fiber optic connector with optical discontinuity monitored.

Learn more about our Temperature and Humidity Testing programs: experiorlabs.com/temperature-humidity-testing

UD T4000 Dual Shaker

Vibration Testing

Shock Testing & Vibration

Testing Capabilities

UD T2000 Dual Shaker

Vibration Testing

Extra Large Payload

Vibration Testing

Vibration testing system can be used in tandem to provide a combined 80,000 lbf for testing large articles.

Transportation Vibration Testing

Experior Labs’ dynamics laboratory can conduct Transportation Vibration testing per MIL-STD-810 Method 514 Procedure II “Loose Cargo Transportation”. During this vibration test, products are subjected to vibration profiles developed to simulate truck and rail shipments. The test severity, in particular, is for loose cargo transport in military vehicles traversing rough terrain.

Acceleration Testing

The main advantage of the Sine Burst is that it is performed on a vibration system, the same vibration system that performs other tests such as random and/or sine sweep vibration and shock testing. Further, test article sizes can be much larger and heavier than in a Centrifuge. Performing all dynamic tests on the same vibration system reduces test costs and time.

High G Vibration Testing

High G Vibration Testing at 149 G rms. Random vibration testing of an electrical connector and backshell.

ORION spacecraft connector and back shell assembly provided by HiRel Connectors and Kern Engineering

Aerospace Test Campaign

T4000 Vibration

The above animation illustrates a proprietary resonance plate the Experior dynamics team designed to amplify the PSD profile generated by the vibration testing system armature and achieve High G levels approaching 200 G rms.

Experior Laboratories specializes in creating high-performing and demanding vibration, shock and vacuum tests associated with rocket launches and space environments. As one of the leading independent test laboratories in North America, Experior Labs is recognized for its superior customer service, consistent on-time delivery, project management by experts and end-to-end accountability.

Learn more about our Space Testing programs: experiorlabs.com/space-testing

Learn more about our Pyroshock Testing programs: experiorlabs.com/srs-shock-testing

Vibration-Test.Com Listing:

experiorlabs.com/srs-shock-testing

Test Standards

Data Sheets

Vibration Testing Expertise

Grace Beech

Grace Beech is one of the project engineers at Experior Laboratories, primarily focused in Dynamics. She is responsible for most of the vibration testing and shock testing performed at Experior Labs. Grace manages various aspects of the vibration testing lab, including fixture design and evaluation, program management, vibration testing capability evaluation, shaker troubleshooting and maintenance, and scheduling.

Grace joined Experior Laboratories in 2014. She brought with her prior engineering experience from her work with Zodiac Aerospace’s business class seating segment, and also from her time as a manufacturing engineer in the vibration testing department at TriSep Corporation. She holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Santa Barbara.

Gerrit Lane

Gerrit Lane joined the Experior Laboratories engineering team in 2015 and has since overseen the successful completion of over 150 environmental test programs. Specializing in dynamics testing and applications, Gerrit has led the design of Experior Laboratories’ pyroshock simulation test system (KIPS), and has designed several custom suites of standard fixtures for vibration testing and shock testing applications.

Gerrit holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Los Angeles.

Kevin Sullivan

Kevin comes to Experior Laboratories with over thirty years’ experience in dynamic testing applications. During his career at Aerojet Rocketdyne he specialized in combined test environments including cryogenically conditioned and pressurized test articles associated with rocket engine components, and supported programs as diverse as the Space Shuttle, International Space Station, expendable rocket propulsion systems, and kinetic energy defense programs. Kevin holds a BSEE from the University of Wyoming.