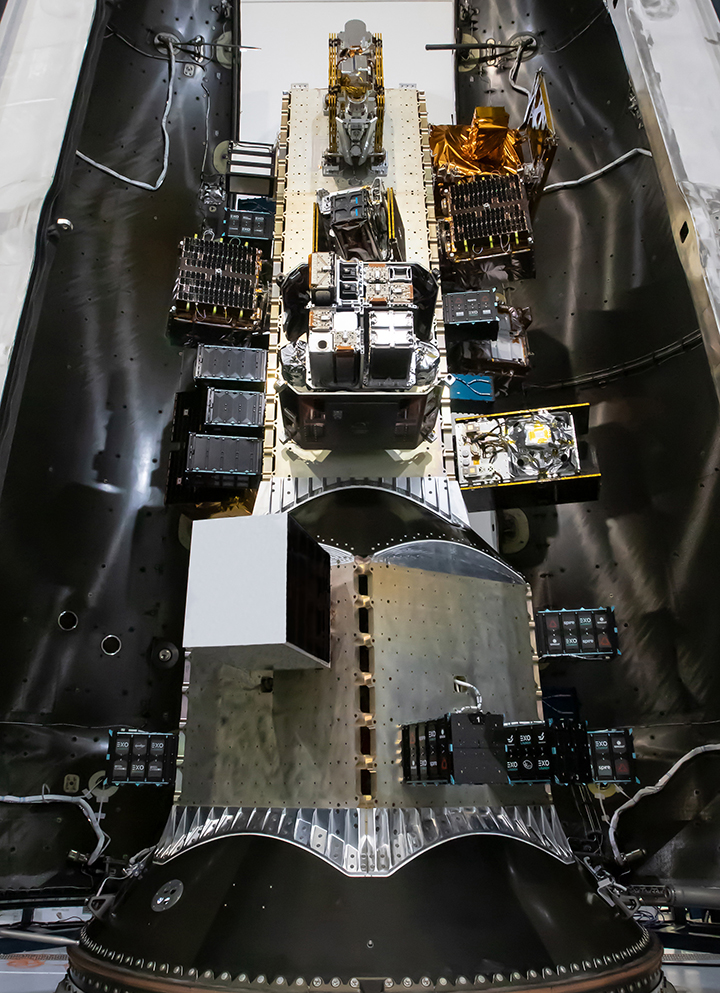

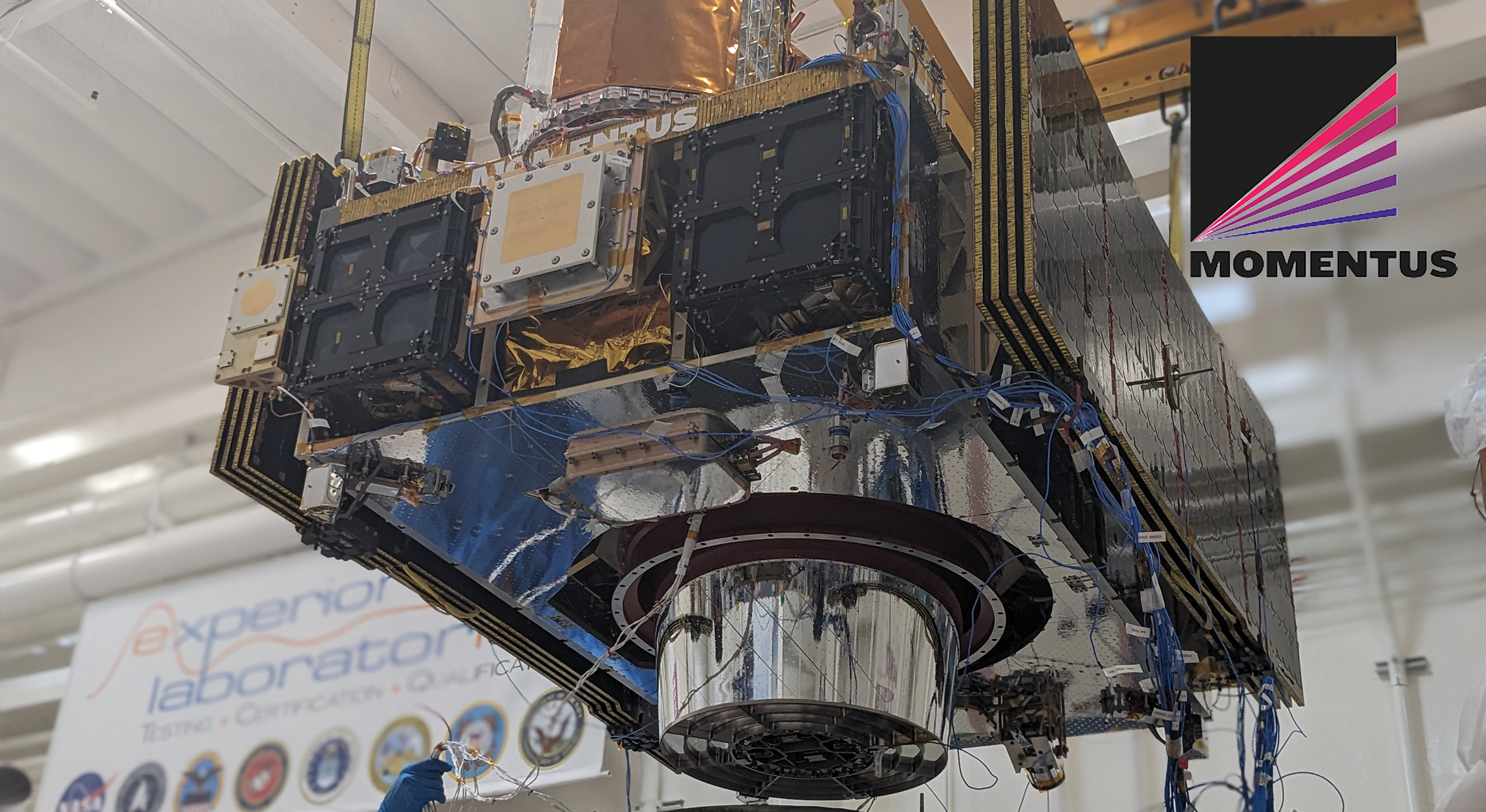

SpaceX Ride-Share Program

Satellite component and systems qualification and testing

Experior Laboratories, Inc. is a leading qualification testing facility that performs frequent flight hardware test campaigns per the SpaceX’ Falcon Payload User Guide (RPUG) for satellites, rideshare busses, solar arrays, propulsion systems, and other payloads launching on SpaceX’ Transporter Missions on a Falcon 9 launch vehicle. Our state-of-the-art testing facilities offer Class 100,000 cleanroom environments for vibration, shock, thermal, vacuum, and direct field acoustic noise testing.

SpaceX Transporter Mission Test Campaigns

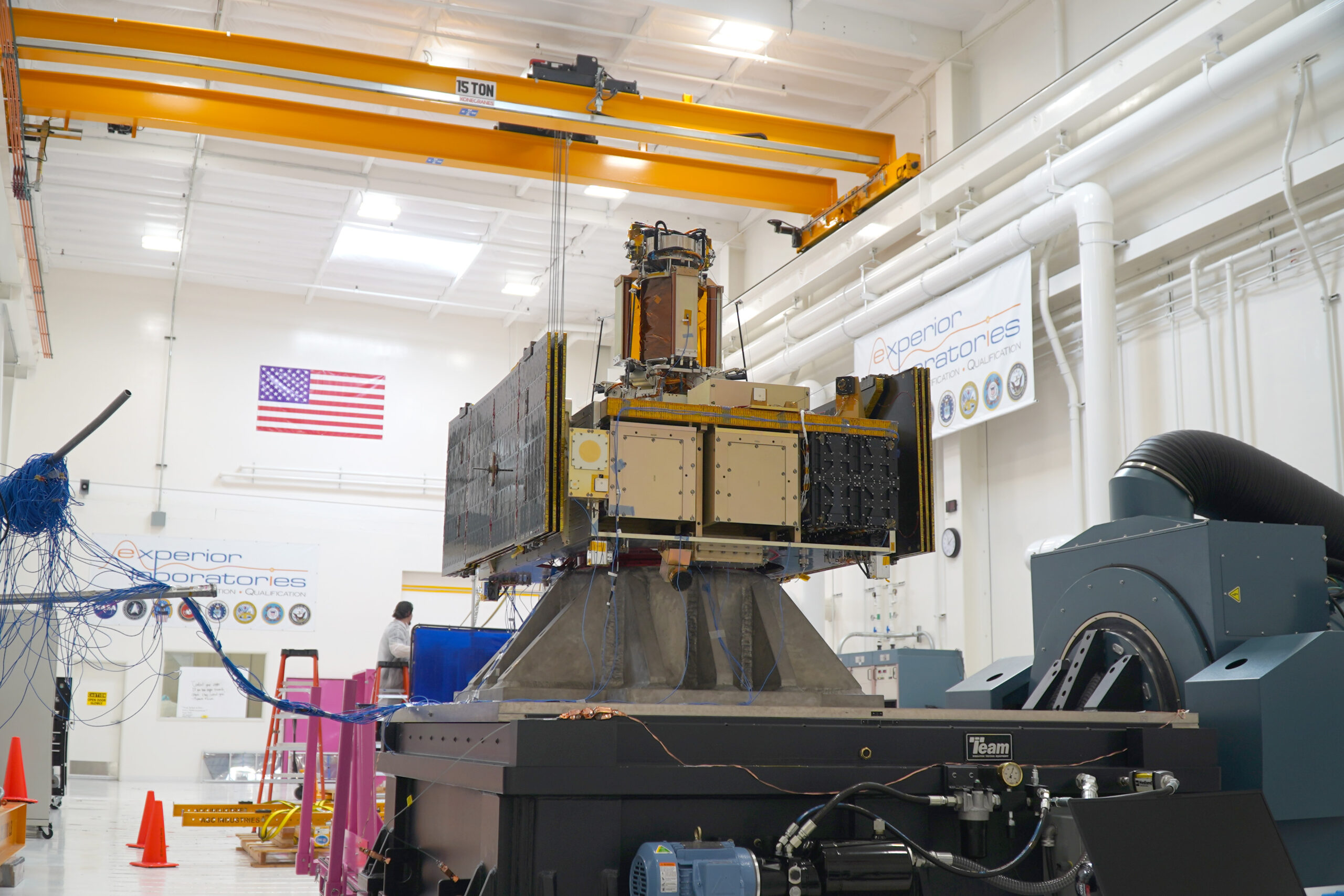

Vibration Testing

Experior Laboratories houses multiple state-of-the-art electrodynamic vibration testing systems that can handle the most demanding vibration and shock testing specifications.

For oversized and heavy payload vibration testing applications, Experior Labs’ vibration testing systems can be used in tandem to provide a combined 80,000 lbf for large articles. Such applications have included rocket engines, rocket stage separation actuators, satellites, orbital reflectors, electric vehicle batteries, railroad components and many more. Custom-made vibration testing fixtures and slip plates allow us to test parts of almost any shape and size.

Pyroshock

Pyroshock testing simulates the high G, high-frequency shock environment associated with pyrotechnic events, such as rocket stage separations. These are sometimes called “SRS Shock” tests, as they are specified with a Shock Response Spectrum (SRS) profile. This profile is a representation of the maximum predicted acceleration of a system across a range of assumed natural frequencies.

Experior Laboratories’ Kinetic Impact Pyroshock Simulation (KIPS) test systems are able to simulate near and midfield Pyroshock, experienced by components closest to a pyrotechnic event, using a high-speed impact to excite a tunable resonant beam.

Direct Field Acoustic Testing

Experior Laboratories partners with industry direct field acoustic testing experts with the mutual goal of offering the most comprehensive overall service portfolio and generating substantial impact for strategic proposals. This partnership of combined strengths promises to provide a superior client experience to our customers within the Military, Aerospace and Space industries

Thermal Vacuum

Cryogenic

Temperature Testing

Experior Laboratories test facility can simulate extreme low cryogenic temperatures for aerospace, fiberoptic and electrical applications. Our cryogenic chambers have liquid nitrogen and liquid helium tanks piped in for rapid chilling and freezing temperatures.

Many space components require Cryogenics Testing for parts and instruments exposed to the extreme temperatures in rockets and orbit.

Fast Ramp Temperature Testing

Experior Laboratories has several accelerated thermal chambers with high-flow blower motors and liquid nitrogen boost designed to transition temperature as quickly as possible, and are ideal for tests with demanding ramp rates.

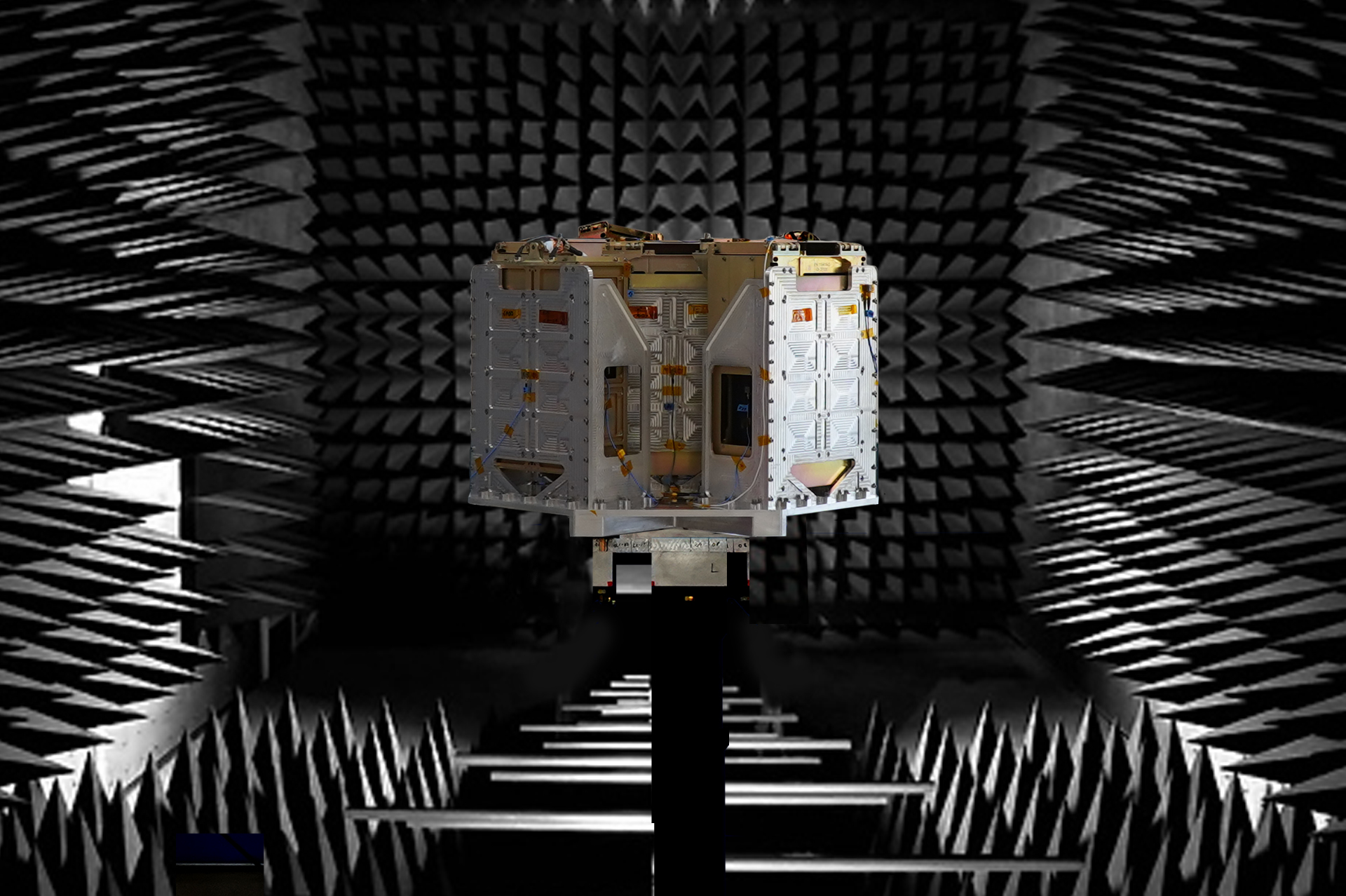

EMI/EMC/HIRF

Experior Laboratories, Inc and DNB Engineering, Inc. are partnering with the mutual goal of offering the most comprehensive overall service portfolio and generating substantial impact for strategic proposals. The partnership promises to provide a superior client experience to our customers within the Aerospace, Military, Automotive, Telecommunication, and Medical industries.

Cleanroom Capacity

Experior Laboratories dynamics testing facility is an ISO8 / Class 100,000 compliant cleanroom, verified and monitored to operate within a temperature range of 71.6°F ± 5.4°F and humidity range of 45% ± 15%.