Mil/Aero Testing

Experior Laboratories is the leading fiber optic and electrical component testing and qualification laboratory with proven global success. Combining extensive industry knowledge, standards development experience and world-class competence, Experior Labs offers a full range of reliable and cost-effective fiber optic and electrical qualification, design verification and reliability testing services.

Experior Labs tests a broad range of fiber optic and electrical components that include fiber, wire, cable, connector and harness assemblies, as well as switches and a range of other passive optical components, including closures and terminals. Experior Labs’ environmental test laboratory features a range of optical and electrical measurement systems with a capacity of hundreds of optical switch channels for testing both, multimode and singlemode components.

Experior Labs is ISO/IEC 17025:2017 accredited, approved to MIL-STD-790 by the Defense Logistics Agency Land and Maritime in Columbus Ohio (DLA), as well as a member of the Verizon Fiber Optic Component (FOC) Independent Test Laboratory (ITL) Program and UL approved under DAP Program

MIL-STD-790 Certification

Vibration at Temperature

Fiber Optic and

Electrical Cable Testing

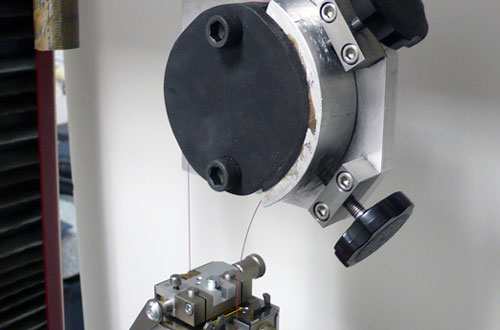

David Ascension sharing some of Experior Laboratories’ fiber optic and electrical cable mechanical testing equipment.

MIL-PRF-29504

MIL-PRF-49291

MIL-PRF-85045

MIL-PRF-28876

MIL-DTL-38999

MIL-PRF-64266

MIL-C-83522

MIL-DTL-83526

MIL-STD-167-1

Mechanical Vibrations

of Shipboard Equipment

This standard specifies procedures and establishes requirements for environmental and internally excited vibration testing of Naval shipboard equipment installed on ships with conventionally shafted propulsion.

MIL-STD-202

Electronic and Electrical

Component Testing

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to MIL-STD-202. The test methods are guidelines set forth by the Department of Defense for electronic and electrical component testing of military products. Experior’s electronics laboratory has the capability to perform many tests.

MIL-STD-810

Environmental Testing

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to MIL-STD-810. The test methods are guidelines set forth by the Department of Defense for general environmental testing of military products. Experior’s equipment, staff, and procedures have continuously and successfully met the stringent requirements of military certification. Experior has the capability to perform many MIL-STD-810 tests.

MIL-STD-1344

Electrical Connector Testing

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to MIL-STD-1344. The test methods are guidelines set forth by the Department of Defense for general electrical connector testing of military components.

NAVMAT P-9492

VITA Open Standards

VITA Technologies are a favorite choice in many critical embedded computing architectures. VITA Technologies adhere to the open system architecture definition of real-time, modular critical embedded computing systems. The developers within the VITA community are committed to technology excellence.

VITA is an incorporated, non-profit organization of vendors and users having a common market interest in real-time, modular embedded computing systems. VITA is accredited as an American National Standards Institute (ANSI) developer. VITA provides members with the ability to develop and to promote open technology standards.

VITA 46 defines the primary digital connector for VPX

VITA 46.30 standard will define VPX connectors with smaller compliant pin tails that support data rates to 25 Gb/s and higher.

VITA 46.31 standard will define comparable connectors with short solder tails for soldering into blind vias in the printed circuit boards.

VITA 67 (ANSI/VITA 67.0-2019) defines the coaxial interconnect base standard for VPX.

VITA 66 (ANSI/VITA 66.0-2016) defines a family of blind mate fiber optic interconnects for VITA 46 backplanes and plug-in modules.

VITA 42 (ANSI/VITA 42.0-2016) defines the switched mezzanine card base specification for XMC cards

VITA 87 is a draft standard for circular optical MT connectors.

ATPD-2404B

Interface Standard Environmental Conditions For Ground Combat Systems

This standard establishes environmental interfaces, nuclear survivability, and Chemical, Biological, Radiological, Nuclear (CBRN) requirements for tracked ground combat systems, to include the Abrams Family of Vehicles (FoV), Bradley FoV, Self-Propelled Howitzer Systems (SPHS) FoV and Armored Multi-Purpose Vehicle (AMPV) FoV, and their integrated subsystems and equipment.

DOD/MIL-STD-1678

Fiber Optic Test Methods and Instrumentation

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to DOD/MIL-STD-1678. The test methods are guidelines set forth by the Department of Defense for general environmental testing of fiber optic products.

EIA-364

Electrical Connector/Socket Test Procedures Including Environmental Classifications

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to EIA-364 series. These documents are procedures set forth by the Electronic Industries Alliance (EIA) for general and environmental testing of electrical connector testing.

EIA-TIA-455

Standard Test Procedure for FiberOptic Fibers, Cables, Transducers, Sensors, Connecting and Terminating Devices, and other Fiber Optic Components

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to EIA-TIA-455 series. These documents are procedures set forth by the Telecommunications Industry Association (TIA) and the Electronic Industries Alliance (EIA) for general testing of fiber optic components.

ARINC Commercial Aerospace Standards

ARINC organizes aviation industry committees and participates in related industry activities that benefit aviation at large by providing technical leadership and guidance.

These activities directly support aviation industry goals: promote safety, efficiency, regularity, and cost-effectiveness in aircraft operations.

ARINC Standards describe avionics, cabin systems, protocols, and interfaces used by more than 10,000 air transport and business aircraft worldwide. There are three classes of ARINC Standards: ARINC Characteristics: Define the form, fit, function, and interfaces of avionics, cabin systems, and aircraft networks.

ARINC 600

ARINC 600 is intended to take advantage of technical and procedural advancements in providing mechanical, electrical, and environmental interface information for air transport avionics “black box” design and installation.

ARINC 801

ARINC Specification 801 is intended to provide standardization of a fiber optic interconnect assembly, which is composed of a connector, fiber optic cable, and fiber optic termini for the air transport industry.

ARINC 802

ARINC Specification 802 is intended to provide standardization of fiber optic cable for the air transport industry.