Mechanical Shock Testing

Mechanical shock testing helps determine whether a device can remain functional when subjected to sudden, abrupt motion changes associated with service environments like product handling, shipping/transportation, rocket stage separation, weapon firing, etc.

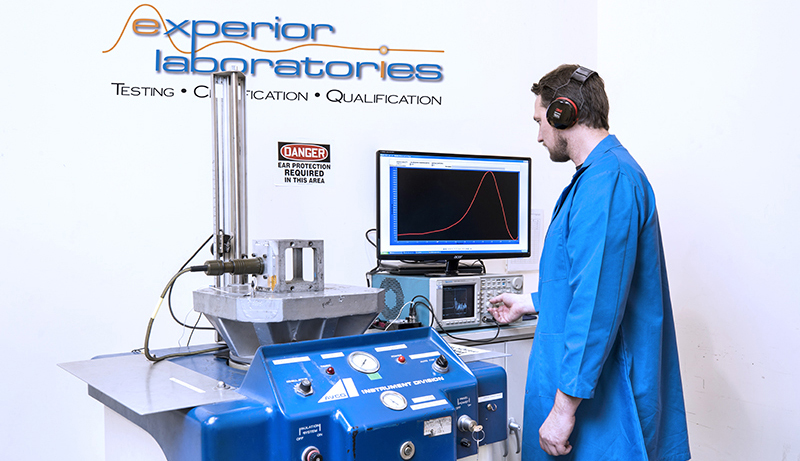

Classical Shock tests such as half-sine, sawtooth, and trapezoidal pulses are associated with product handling events (drop impacts) and transportation induced events (road bumps, pot holes, etc.) and are performed using our AVCO pneumatic shock table or any of our Unholtz-Dickie electrodynamic vibration systems. These shock tests are specified in the Time Domain (acceleration vs. time). Classical shock pulses up to 1,500 g can be accommodated for a wide range of test payloads.

MIL-S-901 Lightweight Shock

Military Specification MIL-S-901 is a military specification for High Impact mechanical shock which applies to equipment mounted on ships. Two levels apply. Grade A items are items which are essential to the safety and continued combat capability of the ship. Grade B items are items whose operation is not essential to the safety and combat capability of the ship but which could become a hazard to personnel, to Grade A items, or to the ship as a whole as a result of exposure to shock. READ MORE

The Lansmont P30 shock system can produce half sine or haversine shocks in excess of 10,000G. Dual elastic accelerators boost the max velocity change to 600in/s or higher. The system comes with pneumatic brakes and a floating seismic base to allow durations as short as .15ms. Data is captured at 1MHz, with shock pulse amplitude and duration reported automatically. SRS plot generation is available.

Test Standards

Experior Laboratories has the expertise to perform shock testing in accordance with an extensive list of Test Specifications, including the partial listing below.

49CFR 178.965

AECTP 400

ATPD-2404B Conditions for ground combat systems

AWES-3362-PR

EIA-364-27 Electrical Connector Shock

EN 62262

EN/IEC 61373 Equipment intended for use on railway vehicles

GR-1209-CORE Component and Module Impact

IEC-60068-2-27 Shock

MIL-STD-810 Method 516.5 Military / Classical Shock

MIL-STD-883 Microelectronics Shock

MIL-STD-202 Electronic Components Shock

MIL-S-901 High Impact shock for equipment mounted on ships

NASA EEE-INST-002

NAVMAT P-9492

RTCA-DO-160 Airborne Equipment Shock

TIA/EIA-455-14 Fiber Optics Shock

Contact Experior to cross-reference your requirements with our complete list of shock test capabilities.

Shock Testing Expertise

Gerrit Lane

Gerrit Lane joined the Experior Laboratories engineering team in 2015 and has since overseen the successful completion of over 150 environmental test programs. Specializing in dynamics testing and applications, Gerrit has led the design of Experior Laboratories’ pyroshock simulation test system (KIPS), and has designed several custom suites of standard fixtures for vibration testing and shock testing applications.

Gerrit holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Los Angeles.

Kevin Sullivan

Kevin comes to Experior Laboratories with over thirty years’ experience in dynamic testing applications. During his career at Aerojet Rocketdyne he specialized in combined test environments including cryogenically conditioned and pressurized test articles associated with rocket engine components, and supported programs as diverse as the Space Shuttle, International Space Station, expendable rocket propulsion systems, and kinetic energy defense programs. Kevin holds a BSEE from the University of Wyoming.