Telecom Testing

Experior Laboratories is the leading fiber optic component testing and qualification laboratory with proven global success. Combining extensive industry knowledge, standards development experience and world-class competence, Experior Labs offers a full range of reliable and cost-effective fiber optic qualification, design verification and reliability testing services.

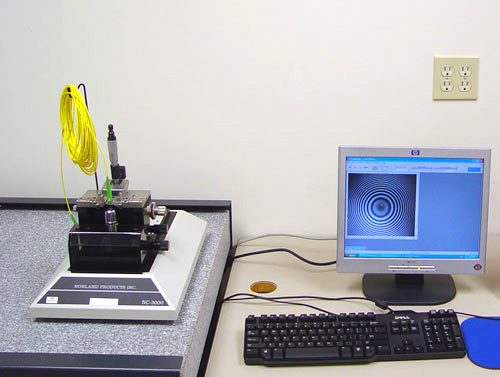

Experior Labs tests a broad range of fiber optic components that include fiber, cable, connector and harness assemblies, as well as switches and a range of other passive optical components, including closures and terminals. Experior Labs’ environmental test laboratory features a range of optical measurement systems with a capacity of hundreds of optical switch channels for testing both multimode and singlemode components.

Experior Labs is ISO/IEC 17025:2017 accredited, a member of the Verizon Fiber Optic Component (FOC) Independent Test Laboratory (ITL) Program, as well as approved to MIL-STD-790 by the Defense Logistics Agency Land and Maritime in Columbus Ohio (DLA) and UL approved under DAP Program.

Verizon Certified ITL Program

UL Approval

Experior Labs is a member of the UL Data Acceptance Program (DAP) which provides means for UL to accept Experior Labs’ test data in support of UL certifications. Experior Labs is recognized as a certified participant of the Third-Party Test Data Program (TPTDP) with specific scope for testing fiber optic components to numerous national and international standards.

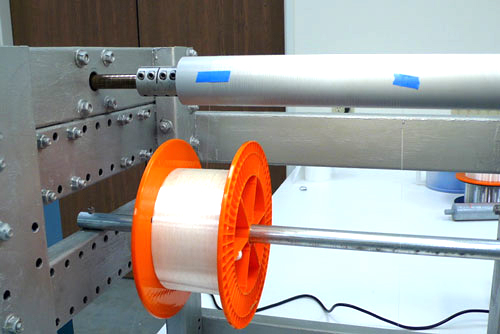

Fiber Optic Testing

David Ascension sharing some of Experior Laboratories’ fiber optic and electrical cable mechanical testing equipment

GR-326-CORE

GR-1081-CORE

GR-1435-CORE

GR-1435-CORE testing aims to qualify singlemode multi-fiber optical connectors (MFOC). MFOCs are used for joining singlemode optical fibers. Fiber types tested can be Media Type I, II, and/or III where each type will have specific conditions.

GR-3120-CORE

GR-3120-CORE testing qualifies hardened fiber optic connectors (HFOC) used in an Outside Plant (OSP) environment. The product may be installed in various environments such as pedestal closures, aerial and buried closures, or on equipment located on a customer premises such as a Fiber Distribution Hub (FDH) or optical network termination unit.

GR-3152-CORE

GR-3152-CORE testing proposes requirements to qualify hardened multi-fiber optical connectors (HMFOC). The plug (male) and jack (female) components are also covered in qualification. The hardened multi-fiber optical connectors are intended to provide drop connections to/from terminals in fiber distribution networks.

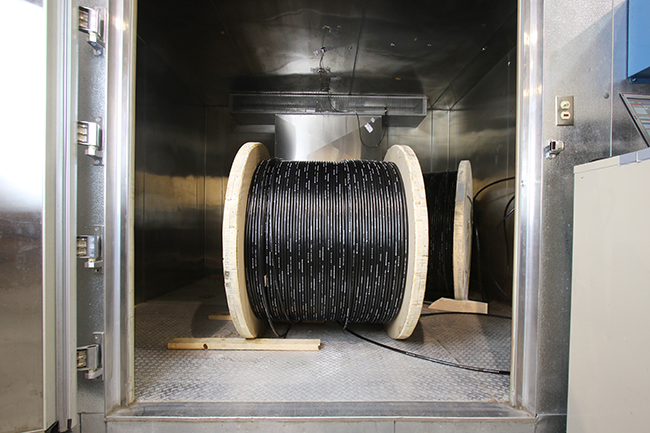

GR-20-CORE

GR-20-CORE, Generic Requirements for Optical Fiber and Optical Fiber Cable, documents the performance and reliability testing requirements to qualify optical fibers and optical fiber cables. This test program applies only to singlemode fibers.

GR-409-CORE

GR-409-CORE Generic Requirements for Premises Fiber Optic Cable is a document specifying testing requirements for singlemode and multimode optical fibers, buffered fibers, optical fiber ribbons, and optical fiber cables.

GR-2866-CORE

Optical testing criteria specified in GR-2866-CORE are to qualify optical fiber fanouts by exposing them to various indoor and outdoor hazards. These potential hazards are then simulated per the required test conditions, methods, and sub-set documents referenced within GR-2866 (TIA/EIA, ASTM, ANSI, and UL 94).

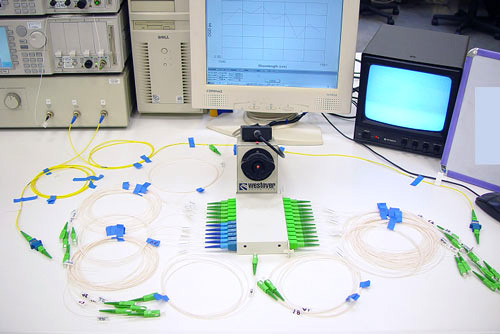

GR-1209-CORE

GR-1209-CORE specifies test requirements to qualify passive optical components. Both singlemode and multimode cables are applicable.

GR-1221-CORE

for Passive Optical Components

Similar to GR-1209-CORE, conditions in GR-1221-CORE testing aims to qualify passive optical components. GR-1221-CORE differs from GR-1209-CORE because the requirements are meant to ensure reliability (extensive use over a large amount of time) of a product while in use for optical equipment and network applications.

GR-449-CORE

for Fiber Distributing Frames

GR-449-CORE describes the general requirements for fiber distributing frames (FDF). Telcommunications service providers typically use an FDF to interface between the outside plant and the central office. An FDF provides fiber optic facilities a cost-effective frame capable of holding a high number of optical cables.

GR-771-CORE

Fiber optic splice closures are enclosures that are intended to restore the environmental and mechanical integrity of one or more fiber cables entering the enclosure and providing some internal function for fiber organization, splicing, termination, or interconnection.

GR-3123-CORE

GR-3123-CORE testing specifies requirements to qualify indoor fiber distribution hubs (FDH). An indoor FDH can be installed on a customer premise in a basement or “telephone room”. This GR considers the FDH to be an outside plant (OSP) closure for use in an uncontrolled environment. Some example of test include:

GR-3125-CORE

Outdoor fiber distribution hub (FDH) serve as the point between a service providers’s central office and the subscriber in a fiber-to-the-home setup. Depending on the size, and FDH can hold hundreds of fiber optical cables, allowing distribution to hundreds of subscribers.

GR-3126-CORE

that Support Fiber Optic Services (Including Fiber to the Premises [FTTP])

These products support the distribution and rollout of fiber optics to the subscribers home. Wall plates for example, create a demarcation point inside the home or building. They are specifically designed to allow appropriate bend radius and allowing enough slack to reach the the premises.

GR-3155-CORE

Fiber microducts help deploy fiber and cables to the premises (home, office, etc). The general requirements specified in GR-3155 describe testing a group of microducts to ensure it can withstand compression, vibration, temperatre stressing, and other factors it might experience over it’s lifecycle.