Vibration Testing

Contact Experior Today To Learn More About Our Vibration Testing Capabilities

805-483-3400

Vibration Testing

Experior Laboratories’ MIL-STD-790 approved and ISO-17025:2017 accredited laboratory houses multiple state-of-the-art electrodynamic vibration testing systems that can handle the most demanding vibration and shock testing specifications.

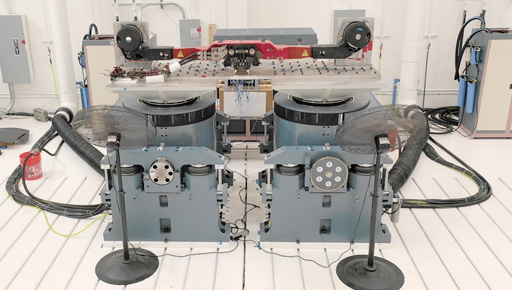

For extreme vibration testing applications of large platforms, Experior Labs vibration testing systems can be used in tandem to provide a combined 80,000 lbf for large articles (example: 14 ft actuator for stage separation). Custom-made vibration testing fixtures and slip plates allow us to test parts of almost any shape and size.

UNHOLTZ-DICKIE – VIBRATION TESTING SYSTEMS

Model T4000

Vibration Testing

T4000 – 2

40,000 lbf

3″ Stroke

Model T2000

Vibration Testing

T2000 – 2

T2000 – 3

25,000 lbf

20,000 lbf

3″ Stroke

2″ Stroke

Model R16C

Vibration Testing

R16C – 2

13,000 lbf

2″ Stroke

Model SO92

Vibration Testing

Vibration Testing Capabilities

Applications

• Sine sweep Vibration Testing: >220 G pk

• Random Vibration Testing: >175 G rms

• Cleanroom Option Available

• Combined Environment Testing from -67° to 170° C

• Up to 128 Channels of Vibration Testing Data Recording

• Time history data recording up to 200kHz

• Sine Sweep Vibration Testing

• Sine Dwell Vibration Testing

• Sine Burst Vibration Testing

• Random Vibration Testing

• Sine on Random Testing

• Random on Random•Vibration Testing

• Windmilling•Vibration Testing

• Gunfire Vibration Testing

• Cargo & Transportation Vibration Testing

High G Vibration Testing

High G Vibration Testing at 149 G rms. Random vibration testing of an electrical connector and backshell.

ORION spacecraft connector and back shell assembly provided by HiRel Connectors and Kern Engineering

Vibration Testing at Temperature

Vibration testing at temperature of Mil/Aero fiber optic connector with optical discontinuity monitored.

The above animation illustrates a proprietary resonance plate the Experior dynamics team designed to amplify the PSD profile generated by the vibration testing system armature and achieve High G levels approaching 200 G rms.

Experior Laboratories specializes in creating high-performing and demanding vibration, shock and vacuum tests associated with rocket launches and space environments. As one of the leading independent test laboratories in North America, Experior Labs is recognized for its superior customer service, consistent on-time delivery, project management by experts and end-to-end accountability. Learn more about our Space Testing programs. experiorlabs.com/space-testing/

Dual Shaker Vibration Testing

Vertical Axis

Extra Large Payload

Vibration Testing

Vibration testing system can be used in tandem to provide a combined 80,000 lbf for testing large articles.

Dual Vibration Testing

Horizontal Axis

Shock Testing & Vibration Testing Capabilities

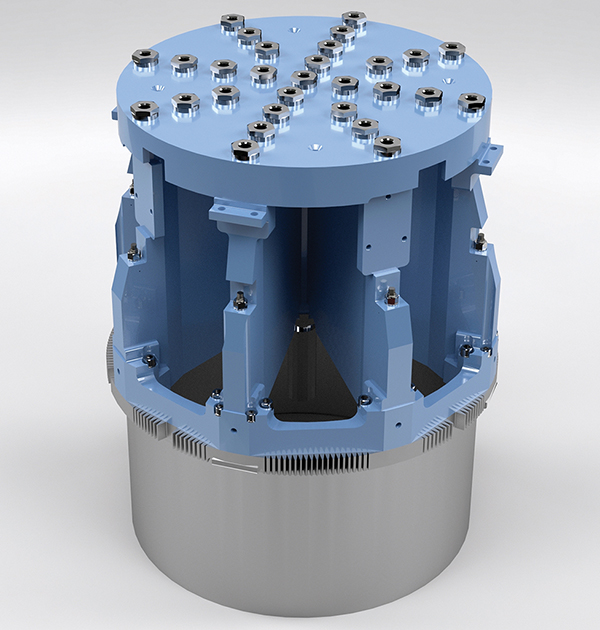

Unholtz-Dickie Vibration Testing System Armature

The Unholtz-Dickie Induct-A-Ring armature uses a solid metal coil with no windings on the moving armature, allowing it to be driven at extreme G-levels without driver coil failure.

By comparison, conventional vibration testing system armatures have a wound coil that’s epoxy bonded to the armature. During High-G level vibration testing operation, this attached driver coil is subject to mechanical failure. It is an accepted fact that conventional driver coil armatures are not well suited for Ultra High-G level vibration testing and shock testing. The Unholtz-Dickie Induct-A-Ring armature solves this problem.

Vibration Testing Expertise

Phil Rogers

Phil Rogers joined Experior Laboratories in 2014 as a Vibration and Shock Testing Specialist, after retiring from Unholtz-Dickie, where he worked as an Applications Engineer and Western Regional Sales Manager for 35+ years. Phil’s detailed knowledge of electrodynamic vibration testing systems and special testing techniques for achieving maximum vibration testing and shock testing performance from these systems is an asset that’s now available to all of Experior Laboratories’ customers.

Grace Beech

Grace Beech is one of the project engineers at Experior Laboratories, primarily focused in Dynamics. She is responsible for most of the vibration testing and shock testing performed at Experior Labs. Grace manages various aspects of the vibration testing lab, including fixture design and evaluation, program management, vibration testing capability evaluation, shaker troubleshooting and maintenance, and scheduling.

Grace joined Experior Laboratories in 2014. She brought with her prior engineering experience from her work with Zodiac Aerospace’s business class seating segment, and also from her time as a manufacturing engineer in the vibration testing department at TriSep Corporation. She holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Santa Barbara.

Gerrit Lane

Gerrit Lane joined the Experior Laboratories engineering team in 2015 and has since overseen the successful completion of over 150 environmental test programs. Specializing in dynamics testing and applications, Gerrit has led the design of Experior Laboratories’ pyroshock simulation test system (KIPS), and has designed several custom suites of standard fixtures for vibration testing and shock testing applications.

Gerrit holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Los Angeles.