CUBESAT TESTING

CubeSat Testing • SmallSat

NASA Approved

JPL Approved

Vibration Testing

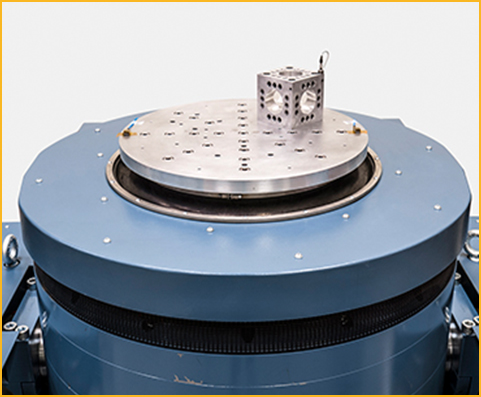

Experior Laboratories houses multiple state-of-the-art electrodynamic vibration testing systems that can handle the most demanding vibration and shock testing specifications.

For oversized and heavy payload vibration testing applications, Experior Labs’ vibration testing systems can be used in tandem to provide a combined 80,000 lbf for large articles. Such applications have included rocket engines, rocket stage separation actuators, satellites, orbital reflectors, electric vehicle batteries, railroad components and many more. Custom-made vibration testing fixtures and slip plates allow us to test parts of almost any shape and size.

Vibration Testing Capabilities

• Sine sweep Vibration Testing: >220 G pk

• Random Vibration Testing: >175 G rms

• Cleanroom Option Available

• Combined Environments: Vibration at hot and cold Temperatures

• Up to > 300 Channels of Vibration Testing Data Recording

• Time history data recording up to 200kHz

Applications

• Sine Sweep Vibration Testing

• Sine Dwell Vibration Testing

• Sine Burst Vibration Testing

• Random Vibration Testing

• Sine on Random Testing

• Random on Random Testing

• Windmilling•Vibration Testing

• Gunfire Vibration Testing

• Cargo & Transportation Vibration

Launch Service Program: Program Level Dispenser and CubeSat Requirements Document

Pyroshock

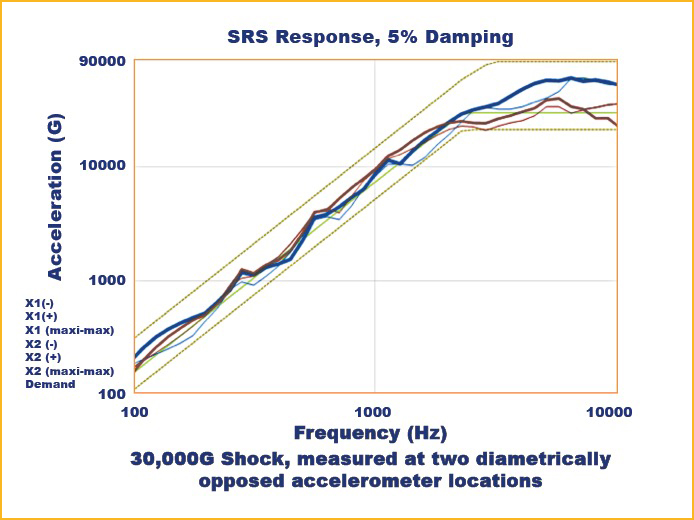

Experior Laboratories’ Kinetic Impact Pyroshock Simulation (KIPS) test systems are able to simulate near and midfield Pyroshock, experienced by components closest to a pyrotechnic event, using a high-speed impact to excite a tunable resonant beam. Adjusting the impact force, location and damping, this platform allows for highly customizable shock generation and the pneumatic systems allow for quick setup and reset.

Adjustable resonance allows boosting acceleration in only the desired frequency range. For shocks with a specified Te (event duration), adjustable muzzle velocity, impact mass, and custom damping materials allow us to customize shock duration while meeting acceleration requirements.

The KIPS test systems offer short transients, narrow differences between positive and negative SRS traces, and a uniform shock input that allows for near-equal measurements at multiple fixture mounting points.

Experior Labs has designed a wide variety of custom shock platforms and fixtures, and we’ve used frequency analysis software to identify mode shapes and resonant frequencies, which lets us prevent cross-axis acceleration and ensure that units are not over-tested.

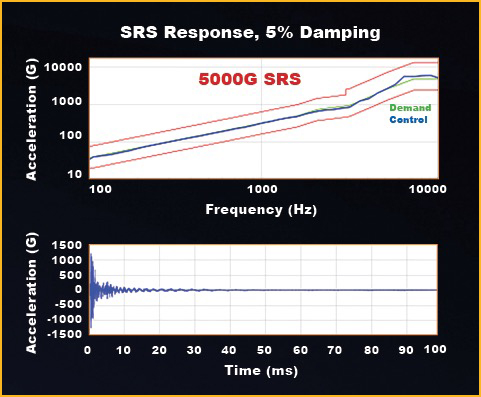

Shaker Shock

Experior Laboratories performs SRS Shock testing with levels up to 5000 G on the T2000 Shakers, making Experior Labs the industry leader in SRS Shaker Shock. Most test labs cannot offer Shaker Shock testing above 500 – 1,000 G SRS due to risk of shaker armature damage.

Thermal Vacuum

Fast Ramp Temperature Testing

Experior Laboratories has several accelerated thermal chambers with high-flow blower motors and liquid nitrogen boost designed to transition temperature as quickly as possible, and are ideal for tests with demanding ramp rates.

Cryogenic

Temperature Testing

Experior Laboratories test facility can simulate extreme low cryogenic temperatures for aerospace, fiberoptic and electrical applications. Our cryogenic chambers have liquid nitrogen and liquid helium tanks piped in for rapid chilling and freezing temperatures.

Many space components require Cryogenics Testing for parts and instruments exposed to the extreme temperatures in rockets and orbit.

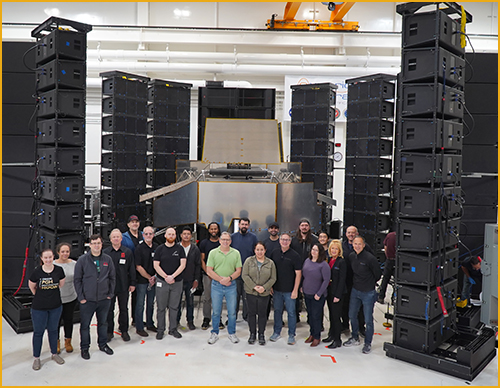

Direct Field Acoustic Testing DFAT / DFAN

Experior Laboratories, Inc and Acoustic Research Systems partnered with the mutual goal of offering the most comprehensive overall service portfolio and generating substantial impact for strategic proposals. This partnership promises to provide a superior client experience to our customers within the Military, Aerospace and Space industries

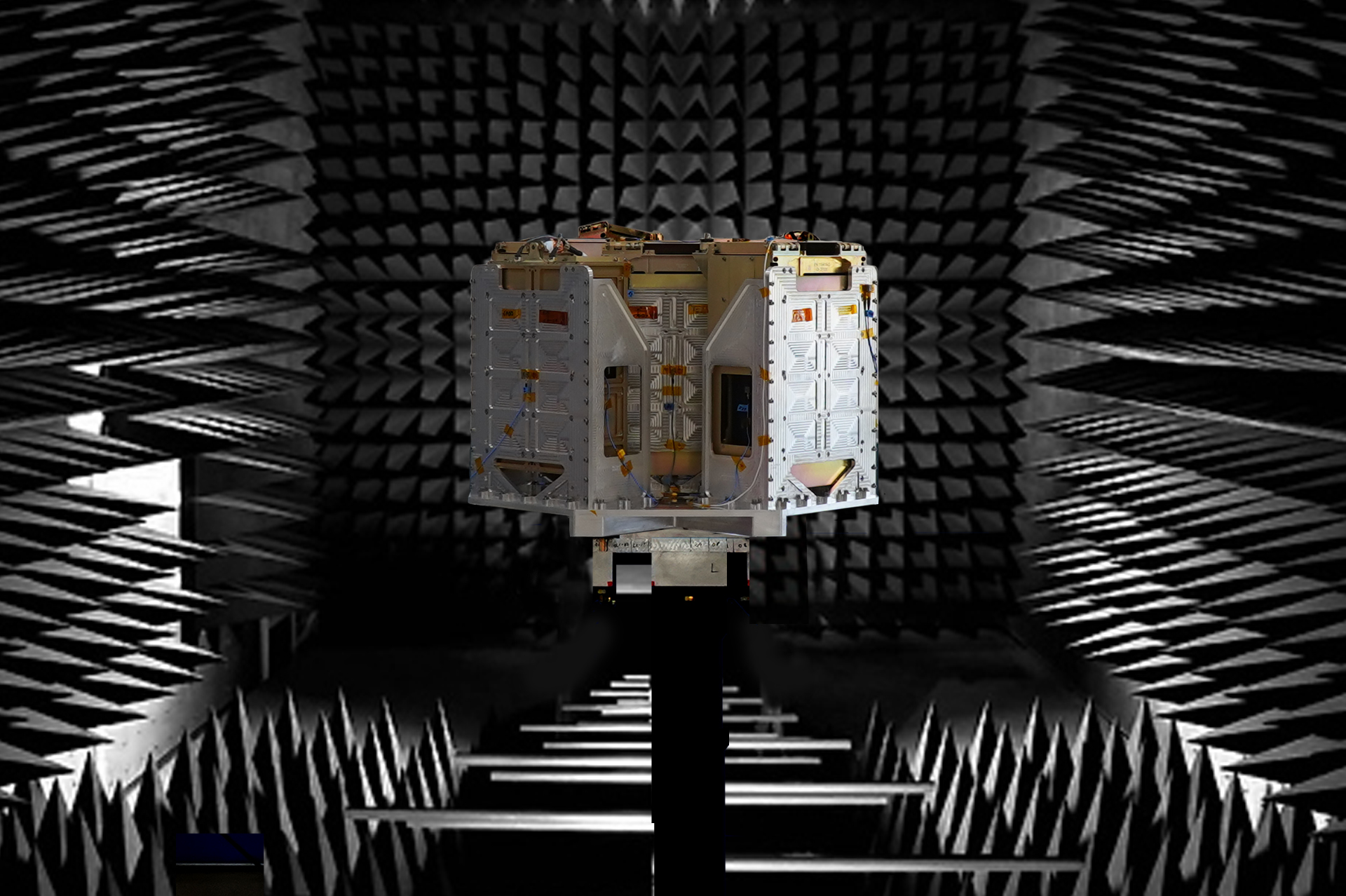

EMI/EMC/HIRF

Experior Laboratories, Inc and DNB Engineering, Inc. are partnering with the mutual goal of offering the most comprehensive overall service portfolio and generating substantial impact for strategic proposals. The partnership promises to provide a superior client experience to our customers within the Aerospace, Military, Automotive, Telecommunication, and Medical industries.

Cleanroom Capacity

Experior Laboratories’ 11,000 square foot dynamics testing facility is an ISO8 / Class 100,000 compliant cleanroom, verified and monitored to operate within a temperature range of 71.6°F ± 5.4°F and humidity range of 45% ± 15%.

Portable Class 100,000 Cleanroom

Experior Labs also offers portable Class 100,000 cleanroom capability to turn any workspace into a cleanroom workspace.

Vibration & Shock Testing Expertise

Grace Beech

Grace Beech is one of the project engineers at Experior Laboratories, primarily focused in Dynamics. She is responsible for most of the vibration testing and shock testing performed at Experior Labs. Grace manages various aspects of the vibration testing lab, including fixture design and evaluation, program management, vibration testing capability evaluation, shaker troubleshooting and maintenance, and scheduling.

Grace joined Experior Laboratories in 2014. She brought with her prior engineering experience from her work with Zodiac Aerospace’s business class seating segment, and also from her time as a manufacturing engineer in the vibration testing department at TriSep Corporation. She holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Santa Barbara.

Gerrit Lane

Gerrit Lane joined the Experior Laboratories engineering team in 2015 and has since overseen the successful completion of over 150 environmental test programs. Specializing in dynamics testing and applications, Gerrit has led the design of Experior Laboratories’ pyroshock simulation test system (KIPS), and has designed several custom suites of standard fixtures for vibration testing and shock testing applications.

Gerrit holds a Bachelor of Science degree in Mechanical Engineering from the University of California, Los Angeles.

Kevin Sullivan

Kevin comes to Experior Laboratories with over thirty years’ experience in dynamic testing applications. During his career at Aerojet Rocketdyne he specialized in combined test environments including cryogenically conditioned and pressurized test articles associated with rocket engine components, and supported programs as diverse as the Space Shuttle, International Space Station, expendable rocket propulsion systems, and kinetic energy defense programs. Kevin holds a BSEE from the University of Wyoming.