Tensile and Compression Testing

The stress on the device can help determine poor workmanship or faulty design. In the case of qualification testing, one may subject their product to a series of tests starting with tensile and compression testing, and subsequently temperature testing, thermal shock testing, or altitude testing. This may show more evidence of damage caused by tensile and compression.

Tensile testing laboratories will have a method of clamping on the device under test. There will also be equipment used to apply the force, which will differ depending on the specific test conducted. It’s also typical to measure conditions such as performance or the applied force vs time chart.

Along with hardness, weight or dimension, tensile and compression testing is common for analyzing material properties. Components used in products should also be subjected to testing. For example, termini and cables are pushed and pulled to determine the force of the insertion and removal point, respectively.

Our laboratory covers a wide range of capabilities including ASTM D 638 for tensile properties of plastics and FED-STD-228 (method 3021 and 3031) for jacket material tensile strength and elongation. All test results (force/displacement/time, etc) are read electronically via digital interface and can be provided in raw electronic format for further processing.

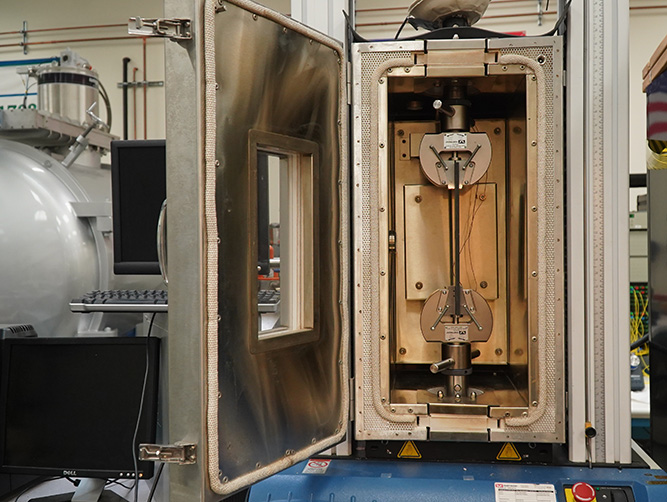

Tensile and Elongation at Temperature of -125C to +300C

For tensile elongation testing, our in-house capabilities for testing of cables and fibers range from low loads to 2,500 pounds and specimen lengths of up to 150 meter. Experior Labs is specifically accredited for these tests to IEC test methods and can also perform tensile elongation testing to various other industry standards.

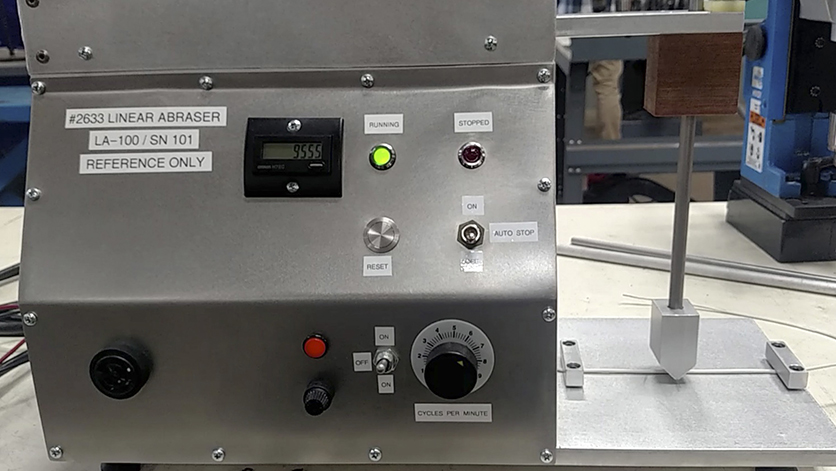

Linear Abrasion Testing:

Experior Laboratories’ Linear Abrasion test system uses a free-floating head to follow the contours of every sample, permitting testing of finished products for abrasion and marking durability. With virtually no limit on sample size or shape, this system is ideal for testing a wide variety of different products. With adjustable stroke length, speed and load, Experior Labs’ linear abrasion setup allow customizing test parameters to any testing needs.

Standard Features:

Stroke Lengths (0.2″ – 3.0″)

Variable stroke speed from 6 – 75 cycles per minute

Variable Load 250 – 2100 grams

Auto stop on wire abrasion break through

Deflection Video

Telcordia GR-20 Optical Cable Twist/Tensile Test

David Ascension sharing Experior Laboratories’ fiber optic and electrical cable mechanical testing equipment