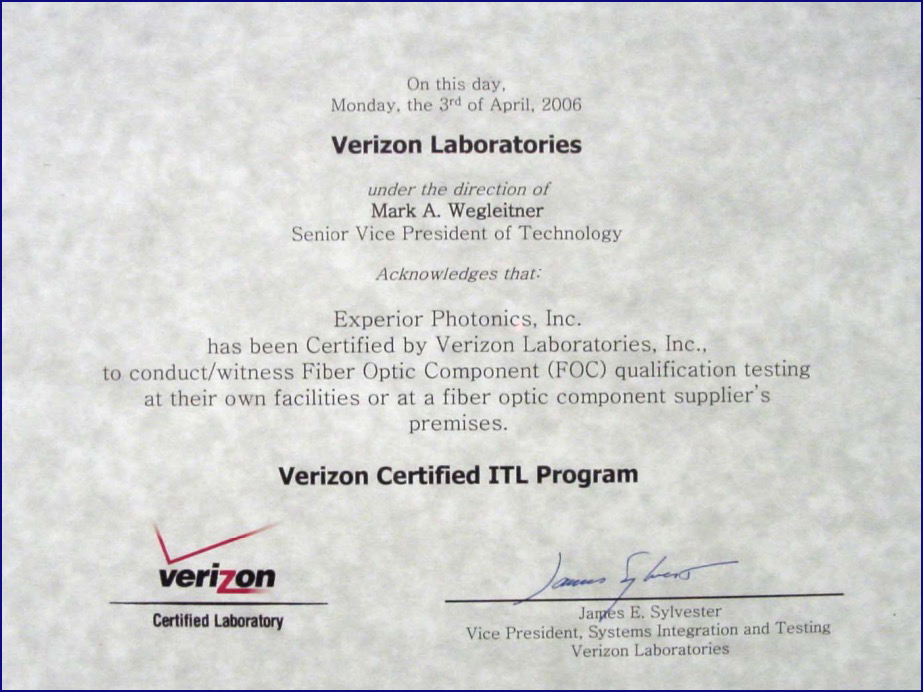

Verizon Certified ITL Program

Telecom Accreditation

Verizon Certified ITL Program

“This program helps expedite product-to-market cycles for Verizon’s telecommunications equipment vendors and creates more economical compliance testing processes for them. Under the Verizon ITL FOC certification program, the selected labs may witness/conduct FOC testing at their own laboratories or at vendors’ facilities that have their own laboratories, which are capable of conducting FOC testing of telecommunications equipment for Verizon. Such testing is essential to confirm that new Fiber Optic Components introduced to Verizon’s network are fully compliant with accepted industry standards.” (Source: Verizon Nebs website) http://www.verizonnebs.com/foc.html

of fiber optic components to the following Telcordia GRs:

GR-20-CORE, Generic Requirements for Optical Fiber and Optical Fiber Cable

GR-326-CORE, Generic Requirements for Single mode Optical Connectors and Jumper Assemblies

GR-409-CORE, Generic Requirements for Premises Fiber Optic Cable

GR-449-CORE, Generic Requirements and Design Considerations for Fiber Distributing Frames

GR-771-CORE, Generic Requirements for Fiber Optic Splice Closures

GR-1081-CORE, Generic Requirements for Field-Mountable Optical Fiber Connectors

GR-1209-CORE, Generic Requirements for Passive Optical Components

GR-1221-CORE, Generic Reliability Assurance Requirements for Passive Optical Components

GR-1435-CORE, Generic Requirements for Multi-Fiber Optical Connectors

GR-2866-CORE, Generic Requirements for Optical Fiber Fanouts

GR-3120-CORE, Generic Requirements for Hardened Fiber Optic Connectors (HFOCs)

GR-3123-CORE, Generic Requirements for Indoor Fiber Distribution Hubs (FDHs)

GR-3125-CORE, Generic Requirements for Outdoor Fiber Distribution Hubs

GR-3126-CORE, Generic Requirements for Wall Plates, Moldings, and Raceways that Support Fiber Optic Services (Including Fiber to the Premises [FTTP])

GR-3152-CORE, Generic Requirements for Hardened Multi-Fiber Optical Connectors (HMFOCs)

GR-3155-CORE, Generic Requirements for Microducts for Fiber Optic Cables

Experior is also approved to conduct onsite audits of manufacturing facilities, a procedure by which Experior and Verizon personnel assess the manufacturing facility to determine acceptability of the assembly, test and shipping of the product. Onsite audits help ensure the proper test equipment, trained personnel, laboratory procedures and TL-9000-based quality system are documented, implemented, and communicated before the fiber optic components are sold to Verizon.

Experior also has the engineering personnel to conduct witness testing at the manufacturer’s laboratory. The test witnesses are Verizon-approved engineers who have already demonstrated their technical expertise in optical measurements, capability in operating laboratory equipment and understanding of the governing GRs and VZ.TPRs. The responsibility of the witness person is to ensure the accuracy of measurements, compliance with the appropriate governing documents and that the manufacturer laboratory satisfies the requirements outlined in the Verizon FOC program. The test witness will also be responsible for authoring the Verizon-formatted report.