Military, Aerospace and Defense Environmental Testing

Ready to Ensure Your Systems Meet Mission Standards?

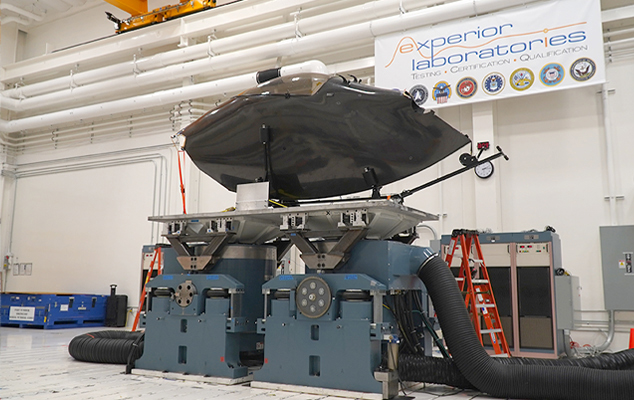

Experior Laboratories specializes in comprehensive environmental testing services tailored to meet the rigorous standards required by the U.S. Military branches and commercial aerospace industry. Our state-of-the-art facilities are equipped to perform a wide range of environmental test services, ensuring they meet the highest standards of durability, reliability, and performance in the most demanding conditions.

Comprehensive Testing Services

Vibration Testing

Shock Testing

MIL-S-901 Lightweight Shock

Military Specification MIL-S-901 is a military specification for High Impact mechanical shock which applies to equipment mounted on ships.

Mechanical Shock Test Methods

Mechanical shock testing helps determine whether a device can remain functional when subjected to sudden, abrupt motion changes associated with service environments.

Temperature and Humidity Testing

Altitude Testing

Fiber Optic and Electrical Cable

and Connector Testing

Military EMC and EMI Testing

Additional Environmental Testing Services

Testing To The Highest Standards

MIL-STD-810

This standard outlines a series of tests to determine the environmental impact on military equipment. It covers a broad range of conditions, including temperature, humidity, shock, vibration, and more.

RTCA DO-160

Used primarily for avionics, this standard specifies the environmental conditions and test procedures for airborne equipment.

MIL-S-901D

Shipboard Machinery, Equipment, and Systems, Shock Testing Requirements.

This standard is specifically concerned with the effects of high-impact shocks that could occur during naval operations, such as those caused by underwater explosions or collisions.

MIL-STD-883

Microelectric Device Testing Procedures

MIL-STD-883 establishes uniform methods, controls, and procedures for testing microelectronic devices suitable for use within Military and Aerospace electronic systems including basic environmental tests to determine resistance to deleterious effects of natural elements and conditions surrounding military and space operations.

MIL-STD-202

Electronic & Electrical Component Testing Standards

MIL-STD-202 establishes uniform methods for testing electronic and electrical components and parts, including basic environmental tests to determine resistance to deleterious effects of natural elements and conditions surrounding military operations, and physical and electrical tests.

ATPD-2404B

Interface Standard Environmental Conditions For Ground Combat Systems

This standard establishes environmental interfaces, nuclear survivability, and Chemical, Biological, Radiological, Nuclear (CBRN) requirements for tracked ground combat systems, include the Abrams Family of Vehicles (FoV), Bradley FoV, Self-Propelled Howitzer Systems (SPHS) FoV and Armored Multi-Purpose Vehicle (AMPV) FoV, and their integrated subsystems and equipment.

NAVMAT P-9492

The NAVMAT P-9492 standard tests the reliability of electronic equipment used by the Navy through a standardized screening process. This involves subjecting equipment to various environmental and operational stresses to identify and rectify potential weaknesses before deployment.

MIL-STD-1344

Electrical Connector Testing

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to MIL-STD-1344. The test methods are guidelines set forth by the Department of Defense for general electrical connector testing of military components.

DOD/MIL-STD-1678

Fiber Optic Test Methods and Instrumentation

Experior Laboratories is approved by the military (DLA Land and Maritime) to conduct testing to DOD/MIL-STD-1678. The test methods are guidelines set forth by the Department of Defense for general environmental testing of fiber optic products.

Military Certification

MIL-STD-790 Certification

Experior has developed internal test procedures for each test method demonstrating knowledge of the military test standard and specification. The internal test procedures are in full compliance with the applicable test method. Experior is approved to conduct qualification testing of optical and electrical components to the following specifications: