LIGHTNING TESTING

+ MILITARY / AEROSPACE EMC TESTING

+ LIGHTNING TESTING

+ HIRF TESTING

+ ELECTROSTATIC DISCHARGE (ESD)

DIRECT LIGHTNING TESTING

The indoor Direct Lightning Test Facility features a large ground plane (32×64 feet) for high voltage attachment testing. The facility also includes a unique Environmentally Controlled Darkroom that is used for both photographic and ignitable mixture (flammable gas) test methods. Another notable feature of the facility is the dedicated Customer Viewing Area where DNB Engineering’s clients can safely watch their tests being conducted.

We can build custom waveforms for specific programs

Our Capabilities Include

• High Voltage Attachment Testing

• Swept Channel Attachment Testing

• High Current Physical Damage Testing

• Structural Testing

• Component Testing

• Fuel System Testing

• Ignitable Mixture Test Method

• Photographic Test Method

• Connector Testing

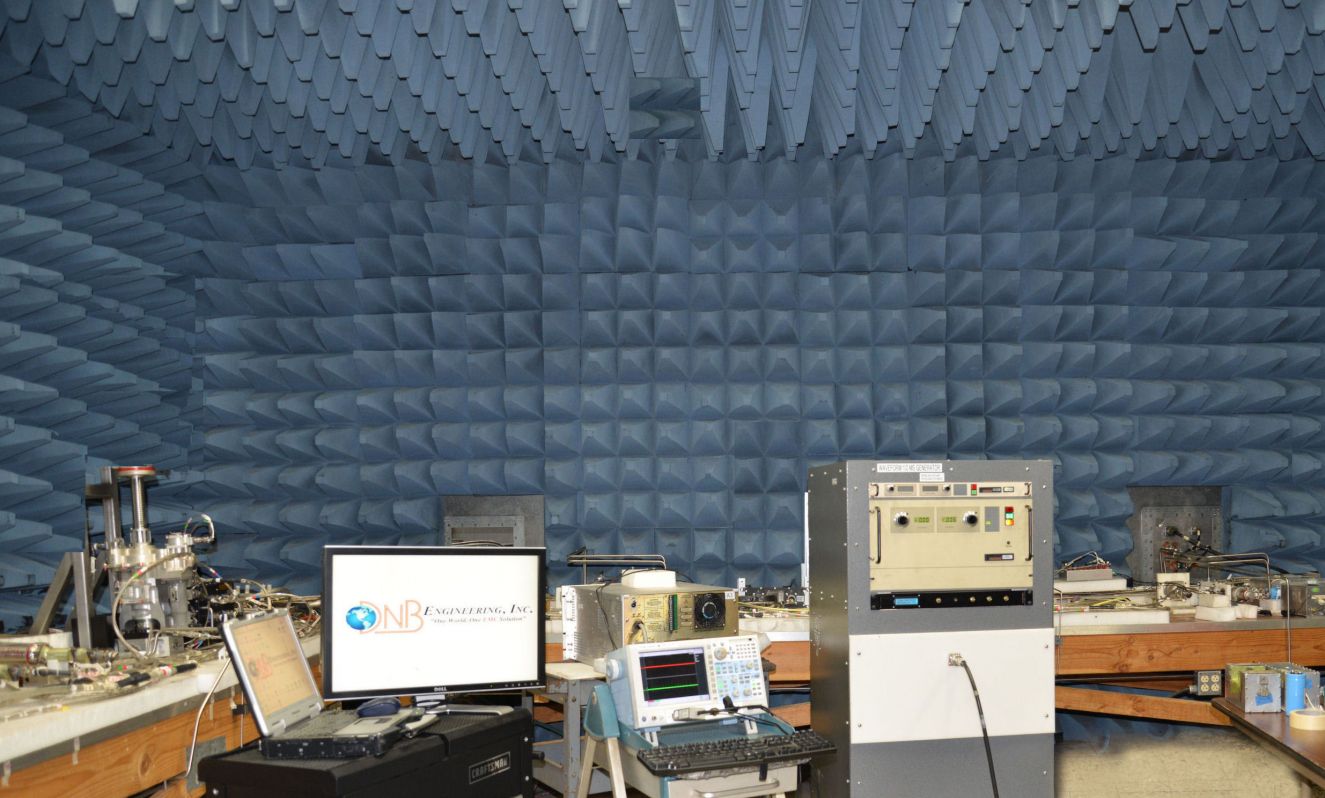

Fully functional direct strike laboratory

• Component A, B, C, D

• 200KA Current component

• 3.0MV High Voltage test

• 3.0MV Marx Generator

We perform all direct effect testing according to the following specifications or requirements:

• RTCA DO-160, Section 23

• SAE ARP5412, ARP5413, ARP5414, ARP5415, ARP5416

• SAE AE4L

• SAE AE2

• MIL-STD-1757

• MIL-STD-464

• FAA AC 20-136

• EUROCAE ED-14D, ED-105

• AS5830

• Near Strike Lightning

• High Voltage Waveforms

1000kV/µs rise time

50 x 250 µs rise time

1.2 x 50 µs rise time

INDIRECT LIGHTNING TESTING

Our Indirect Lightning Capability Includes The Following Specifications:

• RTCA/DO-160 Section 22 / EUROCAE ED-14D

• MIL-STD-461

• AC/AMJ20-53B, SAE AE4L, SAE AE2

• SAE ARP5412 & ARP5416 compliant

• LC1027 (PMG Listing Criteria for Multi-Layer Conductive, Jacketed,

• Corrugated Stainless Steel Tubing)

• Injected Currents to SOKA

| • Induced Effects | • Multiple Burst |

| • Bulk Cable Injection (BCI) | • MIL-STD-1757-T05 |

| • Pin Injection | • Near Strike Lightning |

| • Multiple Stroke | • FAA AC 20-136 |