Environmental Testing

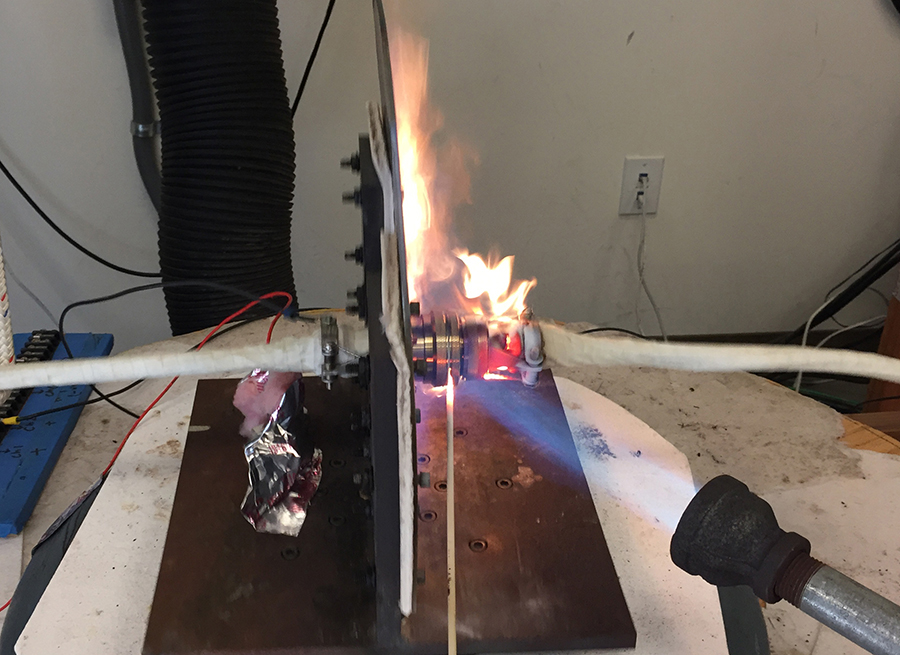

Fire and Flammability Testing

Flammability (sometimes called combustion, fire, or flame) testing exposes the product directly to an external flame. In some procedures or standards, a component successfully passes the fire test if the flame is extinguished within a specified amount of time. Component and device manufacturers will want to subject their product to fire testing to ensure the part becomes self-extinguishing; does not violently burn; does not result in an explosive fire; or that the spreading of the surface burning is prevented.

Flame testing typically requires that a laboratory have a test chamber with adequate venting, fan, and viewing window. The source of the fire comes from a propane torch with an appropriate nozzle. Depending on the test procedure or standard, a timing device, cleaning supplies, and measurement devices can be used.

Many military (MIL-STD and SAE), telecommunication (TIA testing), and industrial manufacturers will want to fire test their product. There are many specifications that require fire testing in part of qualification or reliability testing.

TIA-364-45 Fire Wall Flame Test establishes a test method to determine the ability of a mated electrical firewall connector to resist specified flame and vibration during a 20 minute exposure by preventing the flame from breaching the firewall through the connector, and providing specified electrical performance for the first 6 minutes of the 20 minute exposure.

GR-1209-CORE Generic Requirements for Passive Optical Components specifies a “Flammability” tests for plastic material on optical components that shall not sustain combustion when the flame is removed.

ASTM D5207 Small-Scale Burning Tests specifies a method for Plastic Materials and is used to measure and describe the reaction of components exposed to heat or flame.